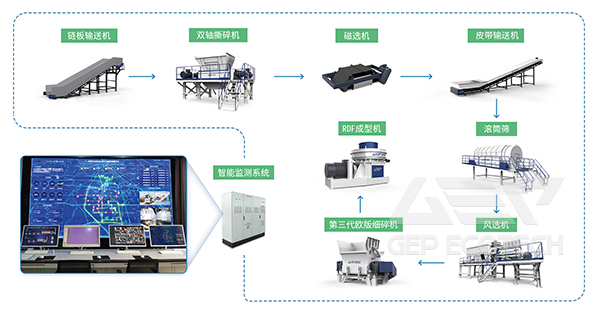

The waste into RDF technology developed by GEP ECOTECH can recycle valuable materials and process them into alternative fuels. The main process is to reduce the volume of combustible waste through coarse crushing, screening, drying, magnetic separation, winnowing, and secondary crushing, and then granulate to make RDF. Because of its considerable calorific value, RDF energy substitutes can help power plants reduce their dependence on coal, oil and other consumable resources, reduce carbon emissions, and reduce the impact of landfills on the environment.

Among them, the successful delivery of the MSW to Alternative Fuel Production Project in the Middle East and the Construction Waste Combustibles to Alternative Fuel Project in Shanghai not only became a benchmark model for regional solid waste resource…

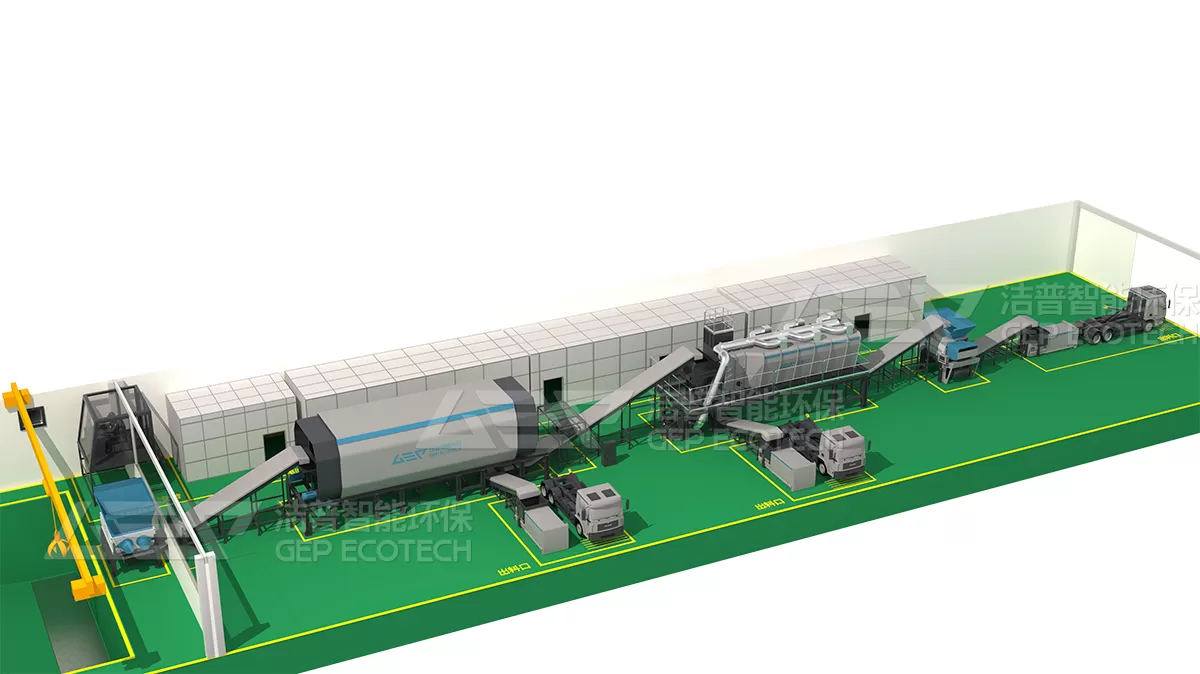

Project OverviewGEP ECOTECH has successfully commissioned a customized domestic waste shredding line in Qatar, designed to efficiently process municipal solid waste (MSW) and produce Refuse-Derived Fuel (RDF) for energy recovery. System Configuration &…

GEP ECOTECH provided a customized RDF production solution for the first waste-derived fuel (RDF) plant in a Middle Eastern country, deploying multiple RDF preparation units to build an intelligent production line with an annual capacity of 55,000 tons.…

Energy Treasure: Re evaluation of the Value of Light Materials in Decoration WasteAbout 30% of the light materials in decoration waste, such as wood, plastic, fabrics, etc., contain enormous energy value. These combustibles can be scientifically…

Driven by carbon peaking and carbon neutrality goals, China continues to promote the clean transformation of high emission industries. With the "14th Five Year Plan" for the development of circular economy clearly proposing the "coordinated disposal of…

Palm fruit fiber, a byproduct of palm oil production, has the potential to be transformed into Refuse-Derived Fuel (RDF) as an alternative energy source. With its renewable nature, calorific value, and abundant supply in palm-producing regions, palm…

As industries strive to address environmental challenges and enhance sustainability, converting waste into fuel has emerged as a significant solution. Industrial shredders play a pivotal role in this process by preparing waste materials for…

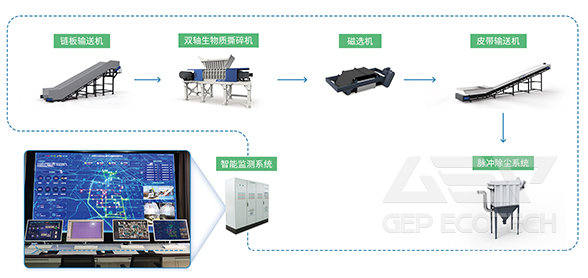

Project profileThe customer is a strong company that does resource disposal of industrial solid waste in China. The processing materials are mainly combustible such as plastic bags, oily paper, waste clothing, and seasonal straw. Through the fully…

The global population growth, urbanization process, and continuous improvement of living standards have all accelerated the generation of waste. The shortage of raw materials and the growing demand for energy have led us to focus on these wastes. The…

The word RDF is familiar to people in the environmental protection industry, especially in the context of dual-carbon, the surging market demand for alternative fuels and the rise of domestic waste resources, making RDF the outlet of solid waste…

GEP ECOTECH is a national high-tech enterprise driven by technological innovation and social responsibility, a provincial-level solid waste equipment technology research center, a provincial-level specialized and refined new enterprise, and a high-…

Jointly hosted by China Building Materials Circulation Association (CBMCA), China Cement Technology Network (CCTN) and China Cement Building Materials Centre, Beijing (BCMC), the "2023 Cement Industry Upgrading and Efficiency Enhancement and Intelligent…

An RDF (Refuse-Derived Fuel) line for bulky municipal waste is a specialized waste processing system designed to convert large and non-homogenous waste, typically generated from households and businesses, into a more uniform and energy-rich fuel. This…

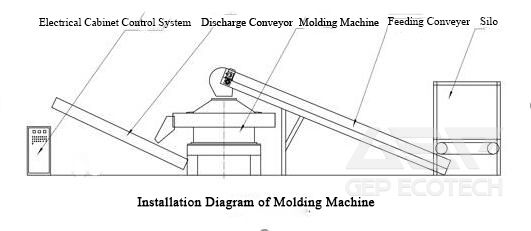

Refuse derived fuel RDF is a fuel made by crushing, sorting, drying, adding chemicals, and compressing combustible waste. In the compression molding process, solid waste molding units are generally used, which include the feeding system, molding system,…

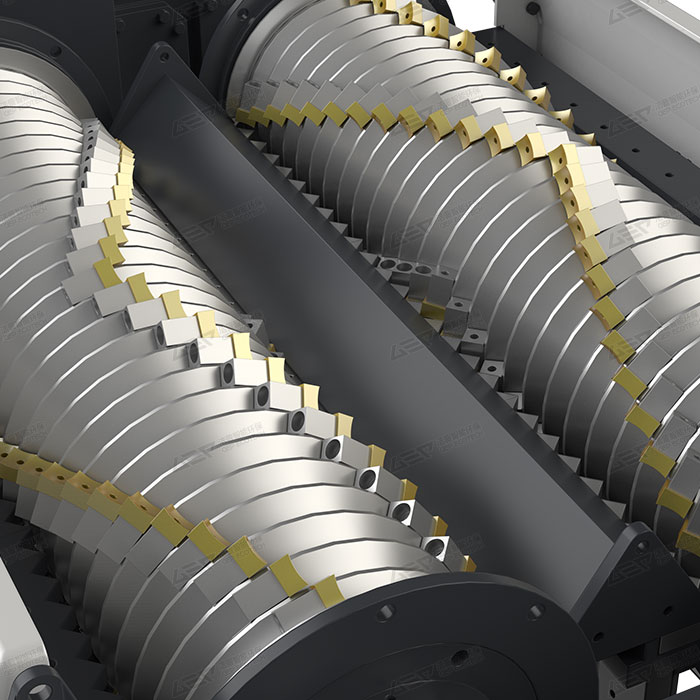

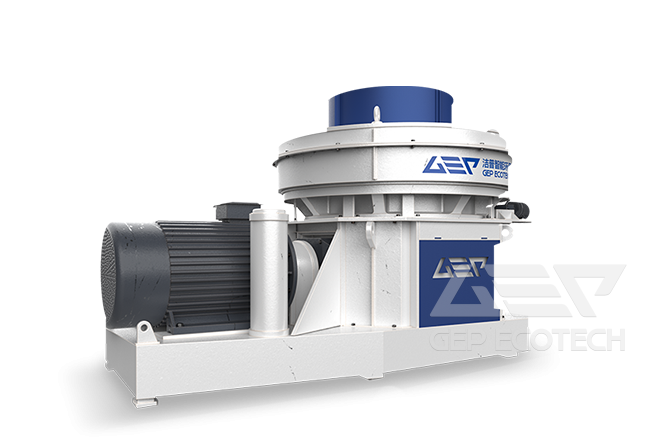

The GPM series RDF forming machine is a solid waste terminal resource utilization equipment developed by GEP, which combines the advantages of similar products. The original design of pressing wheel, module, anti stuffiness machine, full-automatic oil…

Introduction:With the increasing population and rapid urbanization, the usage of disposable products is also on the rise. Among them, diapers are a necessity for infants and adults alike, but the disposal of diaper scraps poses a challenge as they are…

The time when the material is extruded in the mold is one of the most important factors in the operating parameters of the RDF forming machine. The length of its forming time depends on the adjustment of the operating parameters of the forming machine,…

IntroductionWith the acceleration of urbanization, the disposal of used furniture has become an urgent problem. Traditional disposal methods mainly include landfill and incineration, which not only cause environmental pollution but also waste a lot of…

Multi-stage shredding + multi-stage sorting + pelleting, from waste to fuel that is sought after in the market, can actually be so simple!

Industrial production will produce a lot of waste, along with the development of our country economy, industrial waste more and more, along with the development of national environmental protection, industrial solid waste must be properly treated, under…

The amount of RDF (Refuse-Derived Fuel) that can be produced from one ton of household waste can vary depending on several factors, such as the composition of the waste, the efficiency of the RDF production process, and the technology used for RDF…

Industrial waste is generated in the process of industrial production, which will cause great pollution to the environment if it is not properly disposed of. In recent years, one of the emerging solutions is to make industrial waste into RDF alternative…

What is the most popular concept of solid waste treatment? RDF fuel rods are definitely on the list. RDF, short for RefuseDerivedFuel, has high caloric value, stable combustion, easy transportation, easy storage, low secondary pollution and low emissions…

In the Zhejiang industrial waste to RDF project that was put into operation recently, we used the new third-generation single-shaft shredder optimized and upgraded by GEP, with a capacity of 5 tons per hour. This new single-shaft shredder has continuous…

Recently, a customer asked us whether waste woven bags can be turned into RDF? The answer is yes, because woven bags are a kind of plastic, and plastic is a very suitable high-calorie fuel. If used properly, it could partially replace fossil fuels such…

RDF production line consists of shredding, sorting system and pelleting system. Firstly, the solid waste is shredded, combustibles are sorted out, and then dried, and finally extruded to make a granular material—RDF.

Recycling of decoration waste is the general trend. Recently, many customers have asked whether decoration waste can be made into RDF? The answer is yes. The high-calorific-value lightweight materials sorted out after the pretreatment of decoration waste…

Solid recovered fuel is prepared from non-hazardous waste and used in incineration plants or collaborative incineration facilities to achieve energy recovery and reuse.At present, the main solid recovery fuel preparation technologies include drying and…

GPM series RDF pelleting mill is designed with original pressing wheel, module, anti-stuck machine, automatic oil pump, etc. It can make industrial waste, domestic waste, biomass straw, etc. into granular, high-density, high burning value RDF fuel. The…

The rate of MSW generated every year is increasing. Therefore, it is an urgent task to seek a resource-based treatment approach for MSW. Converting MSW into refuse derived fuel, or RDF, is a relatively mature waste treatment method in developed countries…

The equipment of this project consists of the third-generation fine shredder, chain conveyor, belt conveyor, magnetic separator, uniform feeder and RDF pellet mill. Through fully automated crushing, sorting and molding processes, industrial solid wastes…

Today, a customer asked me what the complete set of equipment for RDF processing from domestic waste is. The raw materials are mainly furniture, mattresses, sofas, fabrics, leather in domestic waste. The output requirements are about 800 tons per month.…