Introduction

With the acceleration of urbanization, the disposal of used furniture has become an urgent problem. Traditional disposal methods mainly include landfill and incineration, which not only cause environmental pollution but also waste a lot of resources. Therefore, RDF production technology, as a new type of used furniture treatment technology, has gradually received attention and attention from people.

Principles and Process of RDF Technology

RDF technology refers to the processing of combustible materials in used furniture through classification, separation, crushing, drying, etc., to produce RDF fuel, which is then burned and utilized by specialized equipment. Specifically, the process of RDF preparation technology includes:

Classification: Sort bulky waste such as used furniture by materials such as wood, plastic, metal, etc., to prepare for subsequent separation processing.

Separation: Use methods such as magnetic separation, air flotation, and screening to separate recyclable materials such as metal and plastic from bulky waste such as used furniture in order to achieve the goal of resource recovery.

Crushing: Crush the separated combustible material into a size that is suitable for making RDF fuel.

Drying: Dry the crushed material to ensure the quality and heat value of RDF fuel.

Preparation: Control the density of the dried material, add fuel assistants, and carry out other process steps to produce RDF fuel that meets the standards.

Burning: Burn the prepared RDF fuel in professional equipment to produce energy in the form of electricity, heating, etc.

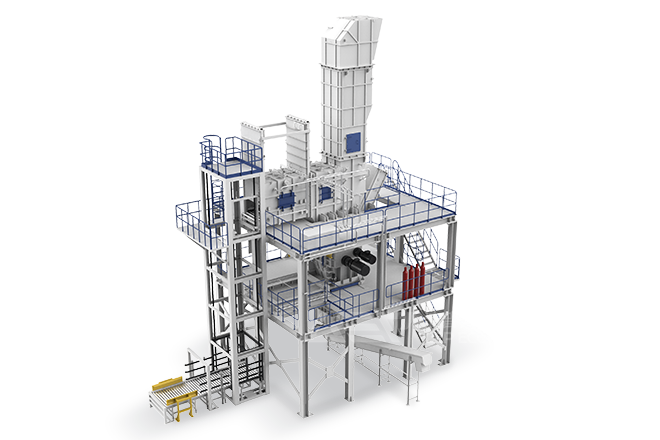

Scrap Furniture RDF Preparation Project Site (Click to Watch the Video)

Applications of RDF Preparation Technology

RDF preparation technology has been widely used in energy utilization, environmental protection, resource recycling, and other fields. In terms of energy utilization, RDF fuel is widely used in electricity and heating, replacing traditional fossil fuels and helping to reduce environmental pollution and save energy. In terms of environmental protection, RDF preparation technology can reduce the impact of bulky waste such as used furniture on the environment and improve the efficiency of waste management. In terms of resource recycling, RDF preparation technology can reuse combustible materials from bulky waste such as used furniture, effectively promoting resource recycling.

Advantages and Disadvantages of RDF Preparation Technology

Compared with traditional waste treatment methods, RDF preparation technology has many advantages, including:

1. Improving the efficiency of waste management. The combustible materials in bulky waste such as used furniture can be effectively separated and processed, significantly improving the efficiency of waste management.

2. Helping the environment. RDF fuel can reduce the emissions of harmful gases such as carbon dioxide during combustion, which is beneficial for improving the environment and protecting the ecological environment.

3. Achieving resource recycling and reuse. Through RDF preparation technology, combustible materials in bulky waste such as used furniture can be reused, achieving the goal of resource recycling and reuse.

However, RDF preparation technology also has some disadvantages, including:

1. Higher preparation costs. RDF preparation technology requires more investment in labor, materials, and money than traditional waste treatment methods, leading to higher preparation costs.

2. Higher requirements for equipment and technology. RDF preparation technology requires professional equipment and technical support, as well as professional personnel to operate and maintain them.

3. Need to solve the emission problems during the RDF combustion process. RDF fuel combustion can produce harmful gases such as carbon dioxide, requiring effective emission treatment.

In conclusion, the treatment of used furniture is an important environmental protection task. Through various waste treatment methods such as RDF preparation, it is possible to effectively reduce the impact of waste on the environment while providing reusable resources for the society.

GEP ECOTECH has been focusing on waste furniture processing technology and equipment production for many years, and has successful waste treatment projects in many areas, such as the Philippines, Malaysia, Hong Kong, Macau, Australia, the United States, Canada, and Mexico. If you have any needs in used furniture recycling, please contact us to get more project experience!