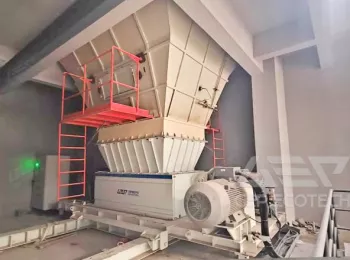

The equipment of this project consists of the third-generation fine shredder, chain conveyor, belt conveyor, magnetic separator, uniform feeder and RDF pellet mill. Through fully automated crushing, sorting and molding processes, industrial solid wastes such as plastic bags, oil paper, waste clothes and other combustible materials are converted into RDF with high calorific value, which are sold to local coal-fired power plants to reduce coal consumption and carbon emissions while gaining considerable economic benefits. The customer said that he is very satisfied with the new fine shredder, which has high efficiency and wide material adaptability. It is especially suitable for industrial solid waste with complex components. The RDF produced have high density, good quality and high price.

Home

{{headline}}

Back

{{headline}}