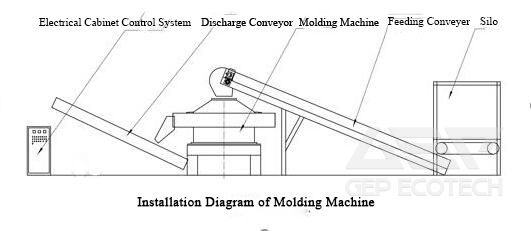

Refuse derived fuel(RDF) is a fuel made by crushing, sorting, drying, adding chemicals, and compressing combustible waste. In the compression molding process, solid waste molding units are generally used, which include the feeding system, molding system, iron removal system, discharge system, heating system, and electrical cabinet control system.

Install

1. Place the molding machine on a solid and flat ground.

2. Place the feeding conveyor in position, adjust the distance to the molding machine and seal it.

3. Place the discharge conveyor in position and adjust the connection position with the molding machine.

4. The electrical control cabinet is in place and connected to the incoming and outgoing lines.

Startup Sequence

Before starting the machine, it is necessary to preheat and warm up. Turn on the heating switch and raise the temperature to 100-120 ℃ before starting the machine. First, press the forward start button of the molding machine. After the molding machine runs for 30 seconds, press the start button of the feeding conveyor, and finally press the start button of the discharge conveyor.

Shutdown sequence

Prepare a wet material with a moisture content of about 50%, and increase it sharply from small to large amounts according to the situation of loose material discharge, until all mold holes release loose material. Press the stop button of the feeding conveyor first, wait until the mold hole of the molding machine is no longer discharging, then press the stop button of the molding machine, and finally press the stop button of the discharging conveyor. After the molding machine is stopped, start and stop it twice, with an interval of 1-2 minutes between each start and stop.