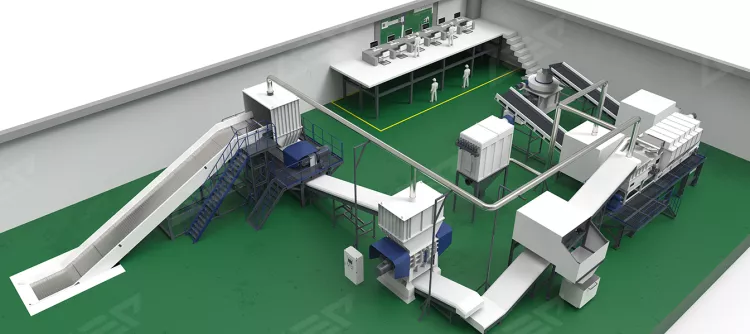

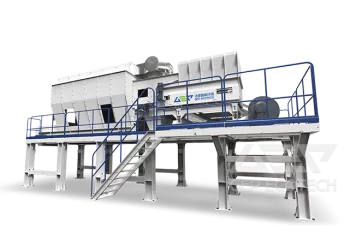

Refuse-Derived Fuel & Solid Recovered Fuel System

After pre-treatment such as bag-breaking and primary magnetic separation, the waste is removed from non-combustible materials such as metal, glass and sand, and the combustible materials in the waste (such as plastic, fibre, rubber, wood and food waste) are fed into the primary shredder, shredded into easily dryable pieces and then sent to the dryer via a conveyor. The moisture content is adjusted by controlling the hot air so that the material moisture is reduced to less than 8%. The dried flue gas is discharged through the dust remover and the dried material is sent to the wind separator after the second magnetic separation. The non-combustible material (ash, broken glass, metal shavings, etc.) is removed again and sent to the secondary shredder, where the material is shredded into small, easily formed particles, to which a certain amount of chemical is added, and then sent to the forming machine. The RDF is produced continuously by the forming machine, then cooled and sent through a vibrating screen into a hopper for the finished product, which is bagged by an automatic weighing machine, while the unqualified material is returned for re-forming.

Benefits of Refuse-Derived Fuel & Solid Recovered Fuel System

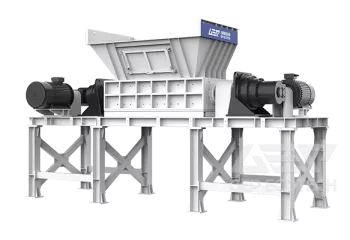

- Powerful and reliable pre-shredding and secondary shredding machine.

- All biodegradable fraction and incombustible fraction(mineral) full separation.

- Optimum material recycling, reduced machine expenditure and energy input.

- The fuel composition, pellet size, and grinding can be matched in the process and adjusted to the needs of the user.

We offer the right technology solution for every application.