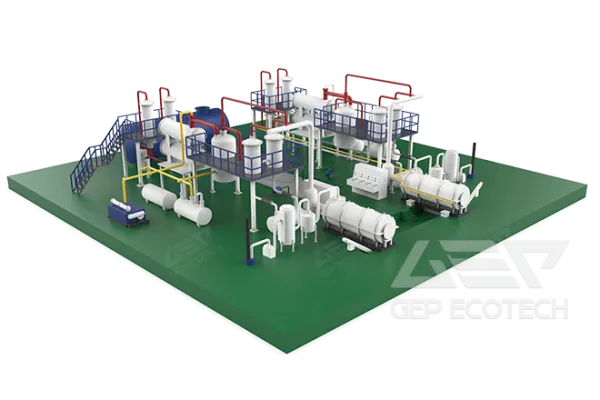

The waste tire pyrolysis and oil refining system is a kind of environmentally friendly equipment that can convert waste tires into usable resources. The core principle is thermal pyrolysis technology, which first pretreats waste tires, such as cleaning to remove surface impurities, cutting them into appropriate sizes, and removing non rubber materials such as steel wires and fibers, to ensure the smooth progress of subsequent pyrolysis processes. The pretreated tire chips enter the pyrolysis furnace, where the higher molecular weight polymers (mainly rubber) in the tires undergo pyrolysis reaction, decomposing into lower molecular weight hydrocarbon compounds, while producing carbon black and gas products. The oil and gas mixture generated by pyrolysis enters the oil and gas separator through pipelines, and is separated by temperature and pressure differences. The separated oil enters the condensation system and is cooled by the condenser to become liquid oil, which is collected in the oil storage tank; The separated gas enters the gas processing system for purification, recovery, or utilization. The carbon black produced by pyrolysis is a valuable by-product. At the bottom of the pyrolysis furnace, carbon black is separated and recovered from the mixture with incompletely pyrolyzed tire residues through specific equipment and can be used to manufacture rubber products, coatings, inks and other products. The entire system not only realizes the resource utilization of waste tires, reduces environmental pollution, but also brings considerable economic benefits.