The materials suitable for processing in this series of heavy-duty hammer crushers include: waste car bodies (excluding engines, gearboxes, fuel, seats, and wheels), tinplate materials (such as cans), bicycles, motorcycles, household appliances and similar household waste, lightweight packaging blocks (density less than 900kg/m3, cross-sectional size less than 250mm × 200mm), empty tanks (such as oil drums, paint drums), steel plates, section steels, and steel products (thickness not more than 4mm).

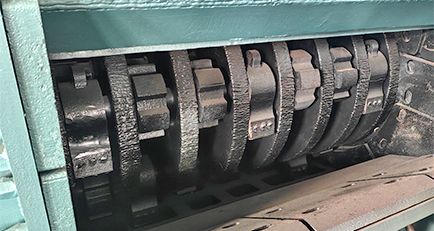

The materials are fed into the hammer crusher, and they are torn into small pieces by the impact of the crushing hammer and anvil driven by the high-power high-speed rotating rotor. By utilizing the space formed between the screen plate and the crushing hammer, under the action of the crushing hammer and the material, the kneading hammer and the material, the material and the material, and the material and the equipment inner cavity, the materials are kneaded into blocks or clumps, and separated from surface oil stains and impurities. After reaching the size of the internal grid holes of the crusher, the materials are discharged from the grid holes.