Wetland management, river maintenance, and ecological restoration projects generate large volumes of biomass waste composed of reeds, sedges, cattails, and other aquatic plants. This type of biomass is difficult to handle due to its fibrous structure, tangled root mats, and inconsistent physical properties. Without proper processing, transportation and disposal costs remain high, and resource utilization becomes impractical.

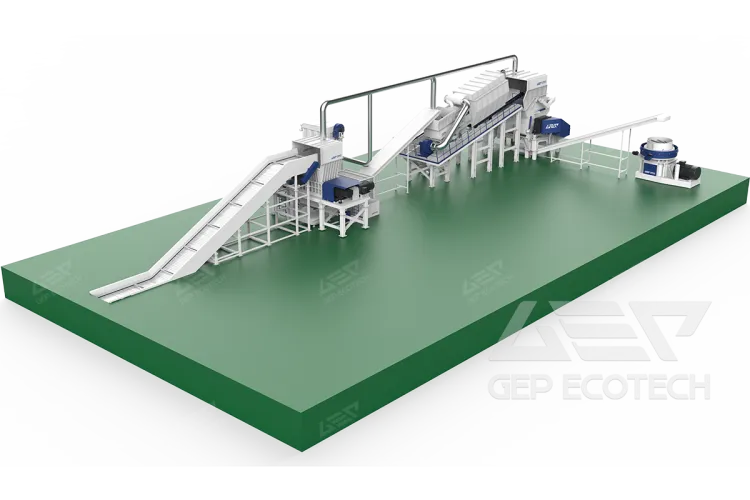

To address these challenges, GEP Ecotech has developed an integrated shredding and briquetting solution for wetland biomass, enabling smooth processing from volume reduction to densification and energy utilization.

Processing Objectives

- Stable shredding of fibrous and root-entangled biomass

- Uniform size reduction to ensure reliable downstream forming

- Briquetting to increase bulk density and fuel value

Recommended Equipment Configuration

1. Double Shaft Shredder

As the core front-end equipment of the system, the double shaft shredder is designed to handle bulky and irregular wetland biomass efficiently.

Key advantages:

Low-speed, high-torque design for long fibers and root mats

Intermeshing shafts to prevent wrapping and clogging

Continuous and uniform output for stable downstream feeding

Suitable for biomass with 10–20% moisture content, without additional drying

2. Hammer Mill

After primary shredding, the material is further reduced to a size suitable for briquetting or pelletizing.

Key features:

High-impact crushing to improve fiber separation

Controlled particle size for consistent forming quality

Suitable for mixed plant-based and woody biomass

Smooth integration with upstream and downstream equipment

3. Briquetting Machine / Pellet Mill

The finely processed biomass is then compressed into dense briquettes or pellets.

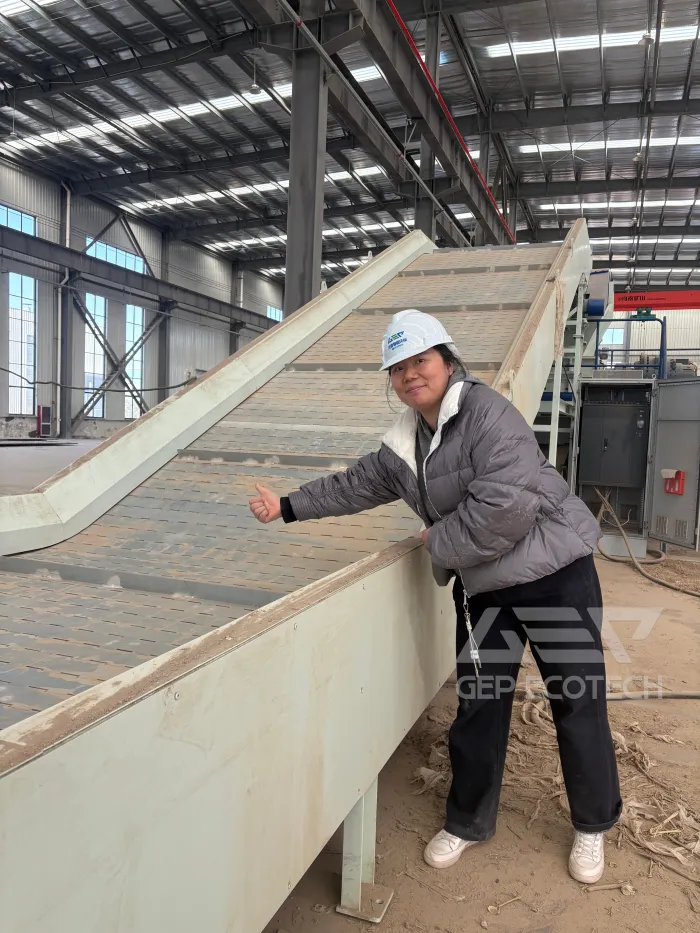

4. Conveying System

A fully integrated conveying system connects all processing stages, ensuring automated material flow, reduced manual handling, and high overall system efficiency.

Typical Applications

- Wetland management and ecological restoration projects

- Centralized processing of dredged river vegetation

- Resource recovery of landscaping and green waste

- Biomass fuel production for heating and power generation

GEP Ecotech delivers more than individual machines. By focusing on system integration and long-term operational stability, we help customers transform difficult-to-handle mixed wetland biomass streams into a sustainable and valuable biomass resource.