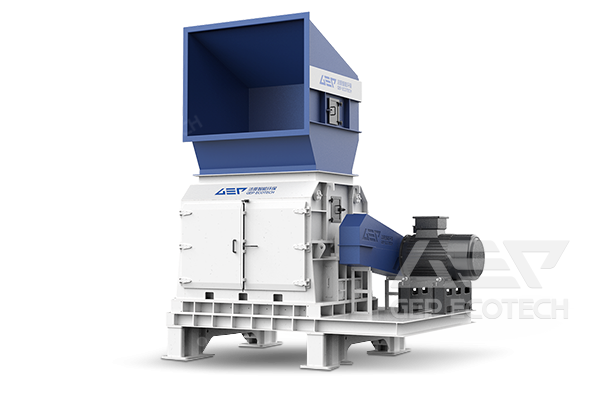

The GXB biomass fine shredder is widely used in various industries, including agricultural and forestry waste treatment, straw shredding, feed production, and chemical processing, offering strong versatility across applications.

The motor drives the rotor at high speed via a V-belt or coupling, enabling the cutter sets mounted on the rotor to gain substantial kinetic energy. Under the combined action of cutting and impact, the material is gradually shredded and pulverized. A large-area screen is installed around the rotor; materials smaller than the screen holes are discharged freely, while oversized particles remain to be shredded in the cutting chamber until the desired particle size is achieved.