Yulong Landfill Project: A Necessary "Root-Cause Cure" for the City

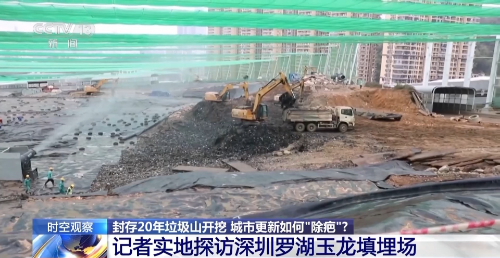

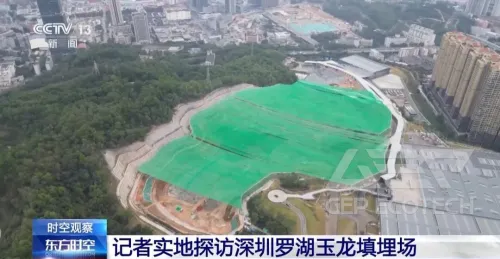

At the foot of Yinhu Mountain in Luohu District, Shenzhen, an unprecedented "urban scar repair operation" is advancing with great urgency. Established in 1983, the Yulong Landfill has accumulated approximately 2.5 million cubic meters of domestic waste, weighing 4.1 million tons, posing long-term environmental hazards such as methane gas leakage, groundwater contamination, and excessive heavy metals in the soil. This site, both a persistent "chronic ailment" troubling nearby residents and a precious urban land resource, urgently requires revitalization as the city's development boundary continues to expand.

In 2024, Shenzhen launched a comprehensive excavation and remediation project with a total investment of 2.17 billion yuan, adopting a "root-out" physical clearance model to fundamentally address long-standing historical issues. The initiative aims to release approximately 30 hectares of contiguous industrial land in one go, achieving a profound transformation from "environmental negative assets" to "ecological positive assets." This effort provides a replicable benchmark for revitalizing existing urban spaces in megacities.

Technical Core: Precision Screening—The "Intelligent Hub" That Transforms Waste into Resources

Excavation serves merely as the starting point of the project. Efficiently and environmentally disposing of vast quantities of aged waste with complex compositions is the key to determining the project's success. The Yulong Project innovatively established a comprehensive process system comprising "rapid aerobic pretreatment + canopy-covered excavation + multi-dimensional composite deodorization + screening for resource utilization." Among these, fine screening acts as the core prerequisite for resource utilization, directly influencing subsequent incineration efficiency and environmental compliance outcomes.

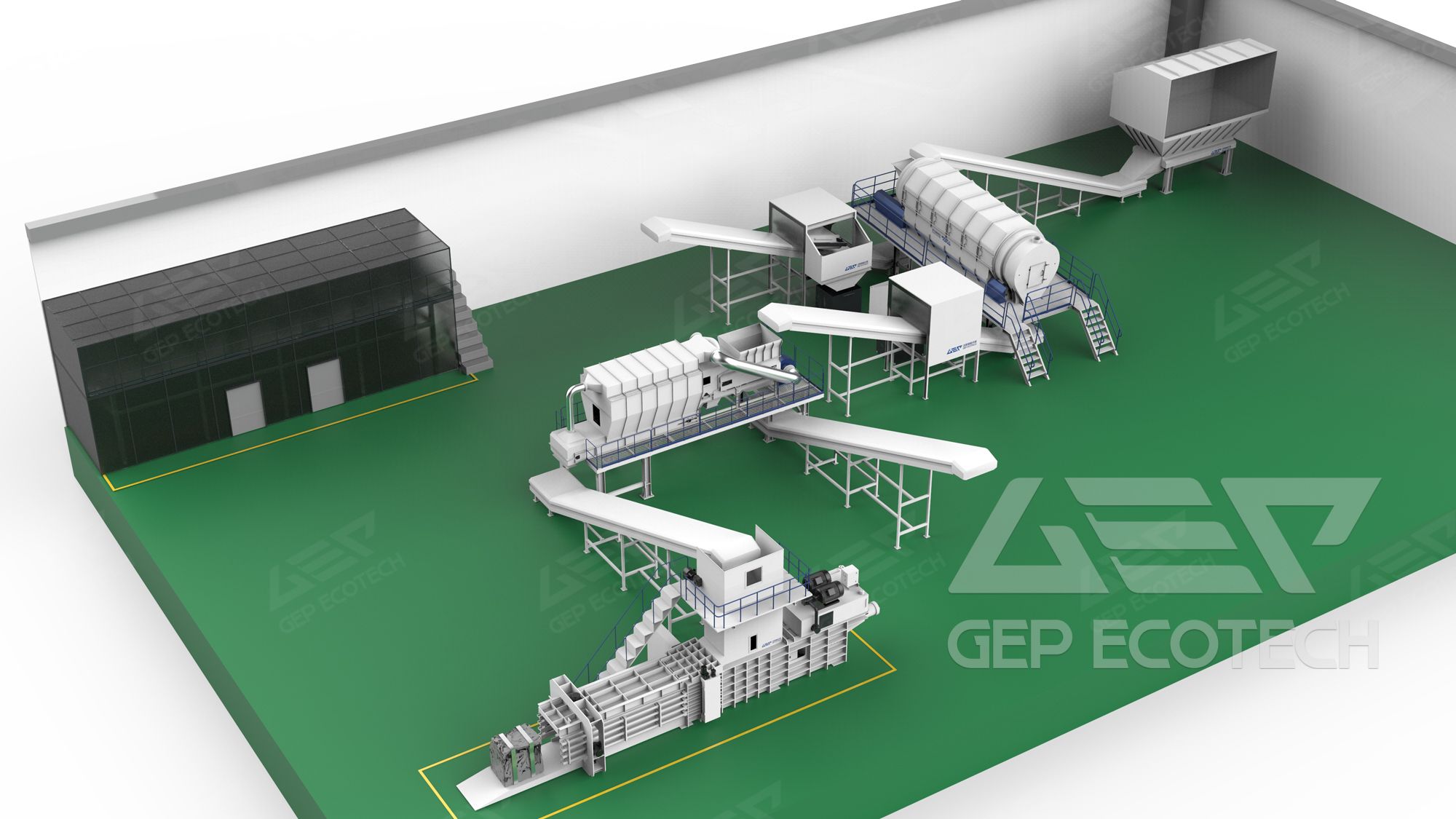

The screening workshop features a fully enclosed design, with six massive conveyor belts capable of processing 6,000 tons of waste daily. Through a five-stage process of "two-stage drum screening + two-stage air separation + one-stage magnetic separation," it achieves precise classification and efficient sorting of aged waste.

- Roller screening: As the first step in the sorting process, it utilizes specially designed screens and adjustable speed mechanisms to initially separate waste by particle size. Coarse particle fractions (such as bricks, stones, and large debris) are recycled as inorganic aggregates, while fine particle fractions (primarily humus soil) are transported for harmless disposal. Lightweight combustible mixtures then proceed to the next stage of sorting.

- Wind sorting: Precisely control wind speed via frequency converters to efficiently separate lightweight combustibles such as plastics and fabrics from humus soil and fine sand, enabling the high-calorific-value combustibles to be utilized as raw materials for incineration power generation, thereby enhancing energy recovery efficiency.

- Magnetic separation: Utilizing a high-intensity magnetic field to adsorb ferrous metals (iron, steel, etc.) from waste, enabling the recycling and reuse of scrap metals while reducing metal impurities' wear on subsequent processing equipment and extending the service life of the machinery.

This five-stage screening system precisely "deconstructs" disorganized waste into clearly controlled resource streams, laying a solid foundation for subsequent harmless disposal and resource utilization.

GEP ECOTECH Solution: Replicating the Efficient Governance Capabilities of Benchmark Projects

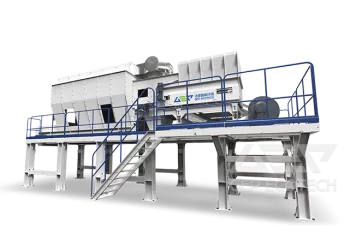

The successful practice of the Yulong Landfill fully validates the feasibility and superiority of the "precise screening + environmentally friendly disposal" model. As a professional environmental protection equipment service provider, GEP ECOTECH can offer a complete set of equipment and customized solutions precisely matched to the core process of this project, supporting the implementation of landfill remediation and waste resource utilization projects across various regions.

Core Advantages of the GEP ECOTECH Solution Lie in:

- Precise sorting with high resource utilization rate: Through a multi-stage mechanical sorting process, it efficiently separates different components such as combustibles, inorganic aggregates, metals, and humus soil, accurately matching disposal pathways for each component, significantly enhancing resource recycling value, and truly achieving "turning waste into resources.".

- Precision manufacturing ensures superior performance and durability: The drum screen features a specially designed anti-clogging mesh and an integrated shaft support structure, delivering low wear, low noise, and strong stability during operation. The air separator is equipped with a variable-frequency air control system, enabling flexible and precise wind speed adjustment for high-purity classification, fewer wear-prone parts, and reduced failure rates, ensuring continuous and efficient operation.

- Intelligent monitoring for cost reduction and efficiency improvement with safety and stability: Equipped with the self-developed GI intelligent monitoring system, it captures real-time operational parameters of equipment, issues early warnings for potential faults, and enables fully automated process operation, ensuring production safety and stability while reducing manual input.

- Environmentally friendly, eliminating secondary pollution: Featuring a fully enclosed operational design, it can be equipped with dedicated dust and odor removal systems to control dust and odor dispersion at the source, meeting stringent environmental requirements for sensitive areas such as residential neighborhoods and central urban districts.

From urban renewal projects in Shenzhen Yulong to those across multiple cities nationwide, landfill remediation has become a crucial lever for unlocking land value and promoting green, low-carbon development. GEP ECOTECH will leverage innovative intelligent equipment and comprehensive solutions, collaborating with various stakeholders to transform more "urban scars" into "fertile grounds for development." By advancing waste resource utilization, we aim to support the construction of "zero-waste cities" and jointly build a future of green development.