I received a call from a customer this morning, saying that there are a lot of waste tires in their vicinity, and asked if we have a good disposal plan and equipment that can recycle these waste tires. Indeed, the recycling of waste tires has high economic and social value. At present, the commonly used ideas for recycling waste tires include: rubber powder production, pyrolysis oil refining, and cement kiln co-processing. Let us understand how to dispose tires through a waste tire shredding recycling project in Southeast Asia.

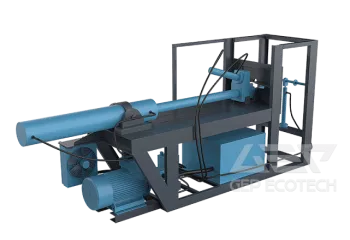

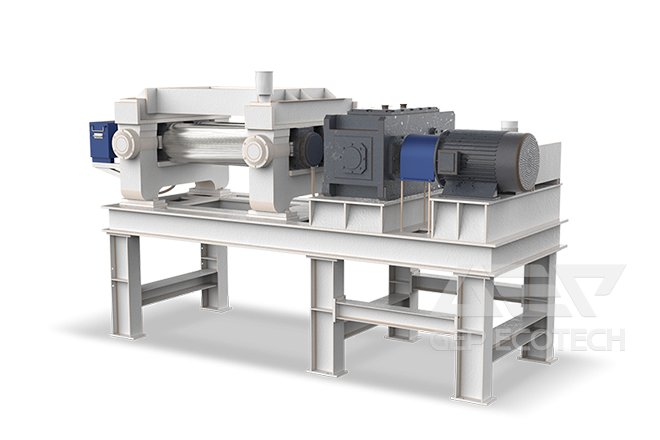

The tyre shredding recycling plant in Southeast Asia mainly consists of a tire wire drawing machine, a chain conveyor, a double-shaft shear shredder, a roller screen, a belt conveyor and an intelligent detection system. The production line adopts intelligent, customized and systematic design, and has the characteristics of small floor space, low investment, low energy consumption, environmental protection, high automation of the whole set of equipment, and easy operation. This series of products has passed CE certification and is manufactured to high standards. It is an ideal equipment for the crushing and disposal of waste tires.

At the tyre shredding recycling site in Southeast Asia, we can see that the waste tires are crushed and sorted through the tyre shredding recycling plant, and then directly enter the tire cracking oil refining series equipment to decompose the waste tires into steel wire, carbon black and fuel oil to solve black pollution. This not only creates green economic benefits, but also promotes the local environmental protection construction process!

The space for the development of additional products for waste tires is very large, and the market prospects are very good. Choosing suitable disposal equipment for waste tire recycling is an important step towards success. GEP ECOTECH has focused on waste tire disposal for many years. If you are interested in waste tire disposal equipment, please contact us for more professional support!