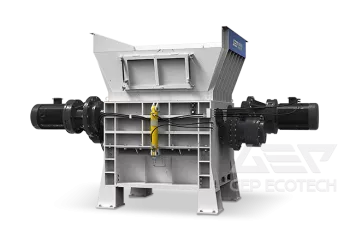

After the end-of-life car and truck tires are recycled, the tire rubber blocks obtained through the processes of wire extraction, shredding and steel wire separation are conveyed to the pyrolysis furnace, which then undergoes anaerobic high temperature cracking to produce renewable resources such as tire oil/heavy oil, carbon black, steel wire/hair and non-condensable gas. GEP ECOTECH CO., LTD customized a complete tire shredding and cracking refinery solution for a waste tire cracking and disposal centre in Southeast Asia. The customer was very satisfied with the 3-4 tones per hour output and 50mm discharge size.

Home

{{headline}}

Back

{{headline}}