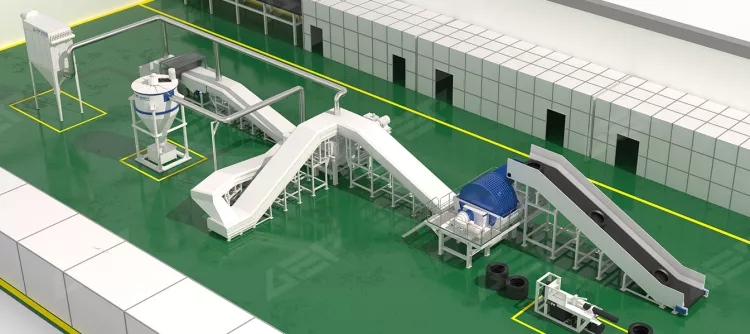

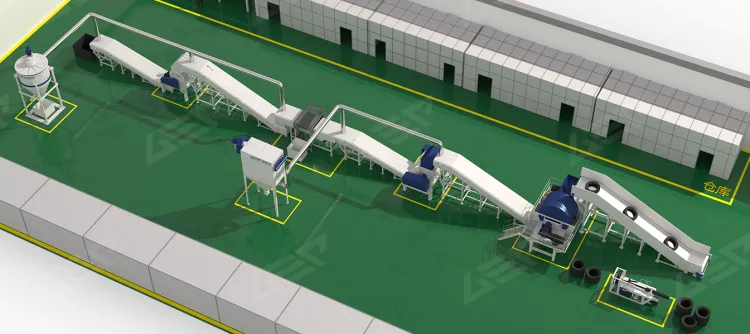

Small-Scale Solution

This is a waste tire recycling solution suitable for small and medium-sized enterprises. The production capacity of a single production line is usually less than 3 tons per hour, main processes include shredding and separation. Rubber blocks (size can be customized), steel wires and fabrics can be separated. Optional equipment includes granulators, rubber breakers and grinders, cracking equipment, dust removal and other equipment.

Benefits of GEP Ecotech Small-Scale Tire Recycling Plant

- Cost-effective, specially developed double-shaft shredder, only one machine can shred the entire tire to the ideal size.

- Flexible configuration, can be equipped with different equipment according to the final application and production requirements.

- Low initial investment cost, Low operating investment, Long-term reliability.

GEP Ecotech designs waste disposal plans according to the specific needs of customers.