Today, we received an inquiry from an Egyptian customer who is looking for a compact yet robust crusher for handling a very specific type of scrap: rejected steel wire products, including wire meshes, shelving frames from household appliances, and similar thin-gauge yet high-tensile items. The required processing capacity is 200 kg/h, and the materials of such materials are shown below — clearly present one of the most notoriously tricky challenges in light steel scrap processing.

This was not just a request for a machine. It was a call for a solution that combines precision, durability, and space efficiency — and we knew exactly what to recommend.

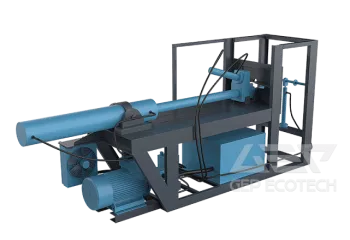

Our recommendation? A small steel crusher GD5 that's custom-built for just this scenario: low-to-medium volume steel wire scrap with high complexity.

What makes it special?

- Twin-shaft configuration, optimized for flexible ferrous materials

- Hardened cutters with anti-wrap geometry, reducing downtime and shaft strain

- Compact design: ideal for tight workshop spaces or localized sorting lines

- Output tailored to 50–200 mm fragments, ideal for resale or briquetting

- Smart controls: Auto-reverse on overload, slow-speed torque mode, and optional hopper guard sensors

- High cost-performance ratio: It delivers professional output at a fraction of the cost of full-size systems. Compared with the a four-shaft steel crusher with the same output, the purchase cost is reduced by more than 20%.

In an age where wire waste is often overlooked yet costly to store and hard to sell unless pre-crushed, having the right crusher turns a liability into revenue.

So whether you're handling rejected wire shelves, stainless mesh trays, or fine gauge steel forms, this compact steel crusher ensures you're not just breaking scrap — you're breaking even, faster.

For more equipment details, please contact us!