Industrial and commercial waste is the solid waste generated from the activities of production and business units. It has a complex composition and may contain various plastics, cardboard, metals, fibers, leather, wood, glass, etc. These materials have a high value for reuse and can be recycled after treatment, into waste-to-energy incineration plants or made into refuse-derived fuels.

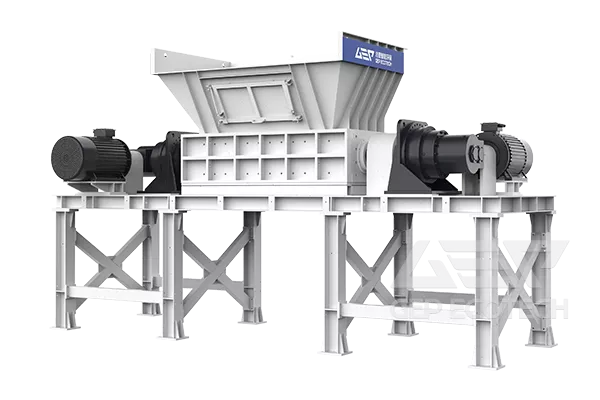

GEP Ecotech's GDI series of industrial waste shredders are ideal for cutting commercial and industrial waste, and for some hazardous solid waste generated by industry and commerce, we have additional specialized equipment for safe disposal.

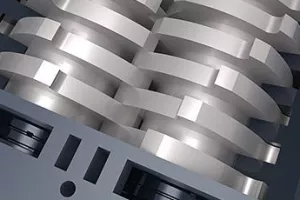

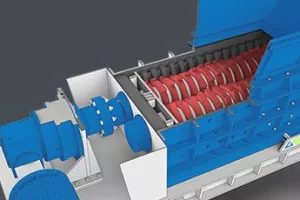

The industrial waste shredder mainly relies on the principle of shearing and cutting to complete the process of shredding materials. The motor drives the reducer and transmits the torque to the shredder's cutters through the cutter roller shaft, which hooks the material and tears it downwards, while the cutters on the relative rollers act like scissors to cut the material. The shredded material is discharged from the bottom of the shredder.