This week, a customized 5 ton/hour double shaft shredder for slaughterhouse waste was successfully packed and shipped to the Philippines.

The Filipino client operates a large-scale slaughterhouse and rendering facility. Their goal: to not only meet environmental standards but to repurpose organic waste into energy through anaerobic digestion. For the biogas plant to work efficiently, the input material — which includes bones, entrails, meat scraps, and fat — must be uniformly reduced to 20mm or smaller, the processing capacity is about 5 tons per hour.

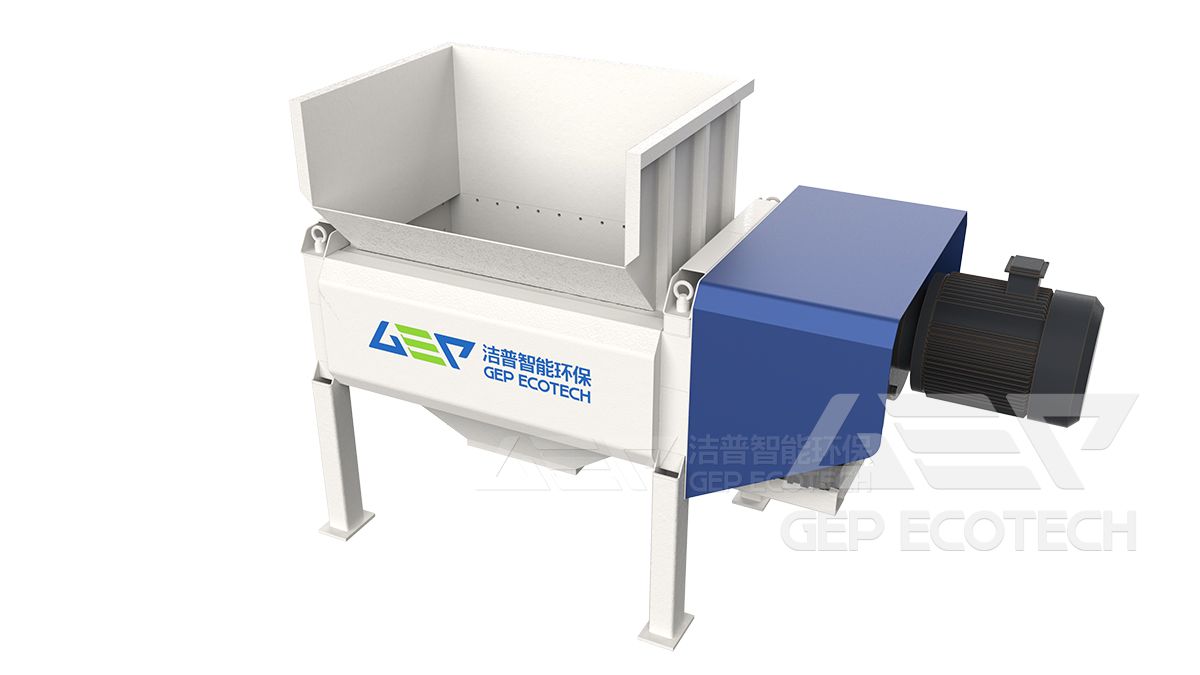

After thorough consultation, we provided a GDF6S double shaft shredder, fully customized for organic animal waste and continuous duty operation.

Key Features of GDF6S:

- Throughput: 4-10 tons per hour

- Final Output Size: 20-100 mm (adjustable), optimized for direct pumping into biogas digesters

- Cutting System: Low-speed, high-torque twin shafts with hardened alloy cutters designed to handle both soft tissue and bone

- Anti-clogging Geometry: Prevents buildup of grease and fibrous matter

- Food-Grade Coating & Stainless Components: Ensures hygiene and corrosion resistance

- Automatic Reverse + Overload Protection: Prevents jamming and reduces downtime

This shipment marks another successful step in helping our partners around the world convert difficult organic waste into a renewable asset. With the right shredder, slaughterhouse byproducts are no longer a disposal problem — they are a fuel, a resource, and a future-forward solution.

For more details on this system or to explore shredders for biogas feed preparation, reach out to our technical team — we're here to engineer smarter waste handling solution from the ground up.