Food waste accounts for about 50%-60% of domestic waste, mainly refers to the perishable, organic domestic waste generated in the daily life of residents and activities such as food processing, catering services and unit feeding, including: waste fats and oils, raw meat remnants, leftovers, bones, etc., and also includes fruit and vegetable waste from vegetable markets.

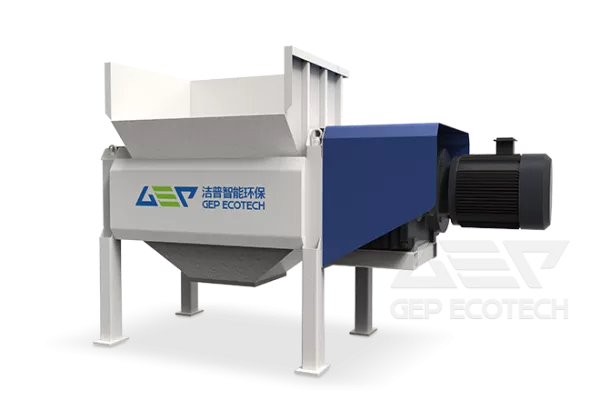

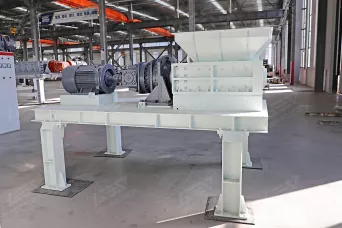

The GDF series double-shaft shearing type shredder has strong shearing and tearing forces to shred all kinds of soft and hard food waste, is anti-corrosion and wear resistant, impact-resistant and can be operated centrally and continuously, making it easy to expand capacity and production. We can also provide professional sewage treatment system, deodorization and dust removal devices to ensure a clean operating environment and light odor.

The GDF series shredder is an intelligent shredding plant designed by GEP Ecotech for the characteristics of kitchen waste, which is highly adaptable to the material and not limited by moisture. The pre-processing of the food waste through the machine provides a high sorting efficiency and a stable material for the subsequent system. This shredder is highly sought after in the market due to the large amount of food waste produced globally every day.

The food waste shredder mainly relies on the principle of shearing and cutting to complete the process of shredding materials. The motor drives the reducer and transmits the torque to the shredder's cutters through the cutter roller shaft, which hooks the material and tears it downwards, while the cutters on the relative rollers act like scissors to cut the material. The shredded material is discharged from the bottom of the shredder.