In order to cope with energy cost pressure and reduce carbon emissions, many cement companies are actively looking for alternatives to coal-fired power generation. Waste textiles, with their advantages of considerable calorific value (average calorific value of about 4300kcal), high volatile matter, low ash content, low moisture content, and low emissions of harmful substances, have become the ideal alternative fuel for cement companies to compete for.

In response to this market demand, GEP has meticulously designed multiple sets of solutions for the preparation of waste textile fuel. These solutions are not only technologically mature, but also feature high efficiency, high stability, and high automation. For material changes such as conventional waste textile fuel and waste textile fuel with more impurities, as well as different needs for processing bulk materials and particles, the intelligent control system can be used to switch to the corresponding mode with one click, making it easy to adjust the process and convenient to use.

Selection of Conventional Waste Textile Shredding

Selection of Waste Textiles With More Impurities

For different materials and processing needs, GEP has made a series of detailed optimizations to the actual operation of various processes, which can make the operation of the production line more efficient and stable, save energy and labor costs, reduce maintenance costs, and improve equipment life

For material winding problems: GEP's GDI double-shaft shredder adopts a patented anti-winding fixed cutter and an independently removable structure, effectively avoiding the winding of waste textiles during the crushing process, improving crushing efficiency and equipment stability, and saving labor and time costs.

For the problem of uneven discharge: The GEP's GSE-3 fine shredder can choose a screen with a suitable aperture according to size requirements, resulting in controllable and uniform discharge size. These manganese steel screens have high hardness and good wear resistance, and the modular structure can be exchanged for use based on wear conditions, reducing costs.

For the problem of high impurities: GEP's patented wind sifter uses frequency control to flexibly adjust the airflow according to the material composition and sorting requirements for efficient sorting. Its unique sorting structure and airflow circulation system ensure higher sorting efficiency, lower system energy consumption, and longer service life.

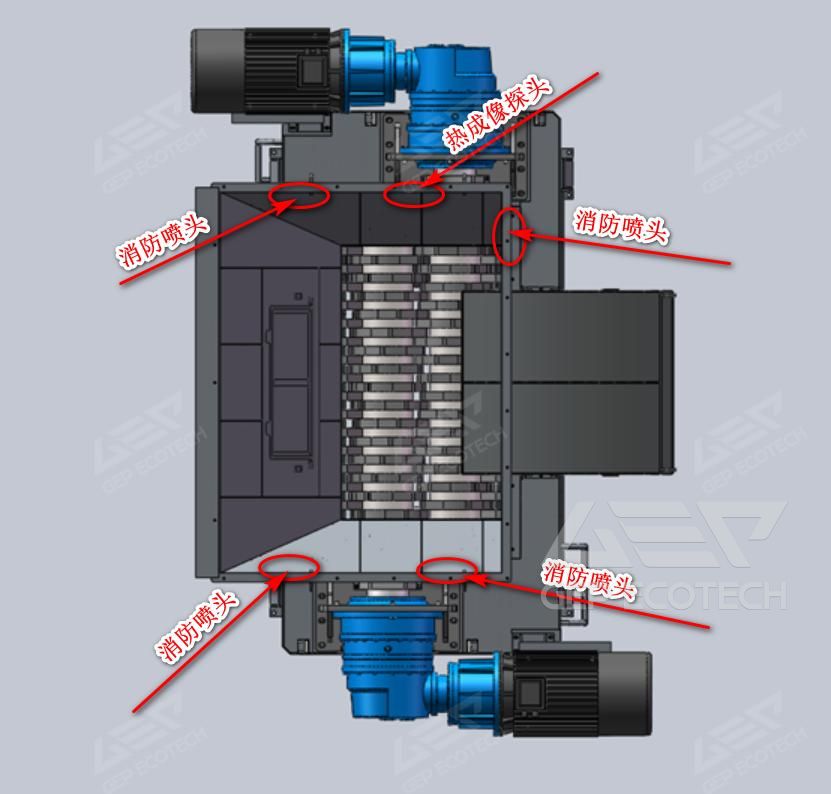

For the flammable materials: the equipment is equipped with professional instruments such as spark detectors and infrared thermal imaging detectors. These instruments can monitor the sparks and heat in the production process in real time, detect and deal with them in time, and give early warnings to effectively prevent fire accidents.

For the problem of efficiency and energy consumption: The introduction of GEP's unique GI intelligent monitoring system can achieve automatic alarming, automatic reverse protection, automatic oil injection and lubrication, real-time status monitoring, and production line linkage control. It not only reduces operating energy consumption and improves production line efficiency, but also ensures production safety.

The cement enterprises that are "difficult to reduce emissions" have entered the countdown to be included in the national carbon market. The increasingly mature technology of waste textile fuelization, as one of the key ways for the cement industry to achieve green transformation and reduce carbon emissions, will usher in new development opportunities.