PVC shredders play a crucial role in recycling and waste management by breaking down PVC materials into smaller, manageable pieces for further processing. These shredders come in two main configurations: single shaft and double shaft. Both types serve different purposes depending on the material’s nature and the desired output.

Single and Double Shaft Shredders for Crushing Hard PVC Materials

Single Shaft PVC Shredder

A single shaft shredder has a rotor with sharp cutting blades and a stationary screen, through which the shredded material passes once it reaches the desired size. It is best suited for processing lighter, less dense PVC materials.

Key Features:

- Precision Shredding: Single shaft shredders offer finer control over the particle size, making them ideal for applications where uniform output is essential.

- Hydraulic Ram: The material is pushed against the rotor using a hydraulic ram, ensuring steady feeding and preventing clogging.

- Lower Capacity: These shredders are typically used in operations with lower volume requirements.

Best Applications:

- Light PVC pipes, films, and sheets.

- Recycling facilities requiring consistent, smaller particle sizes.

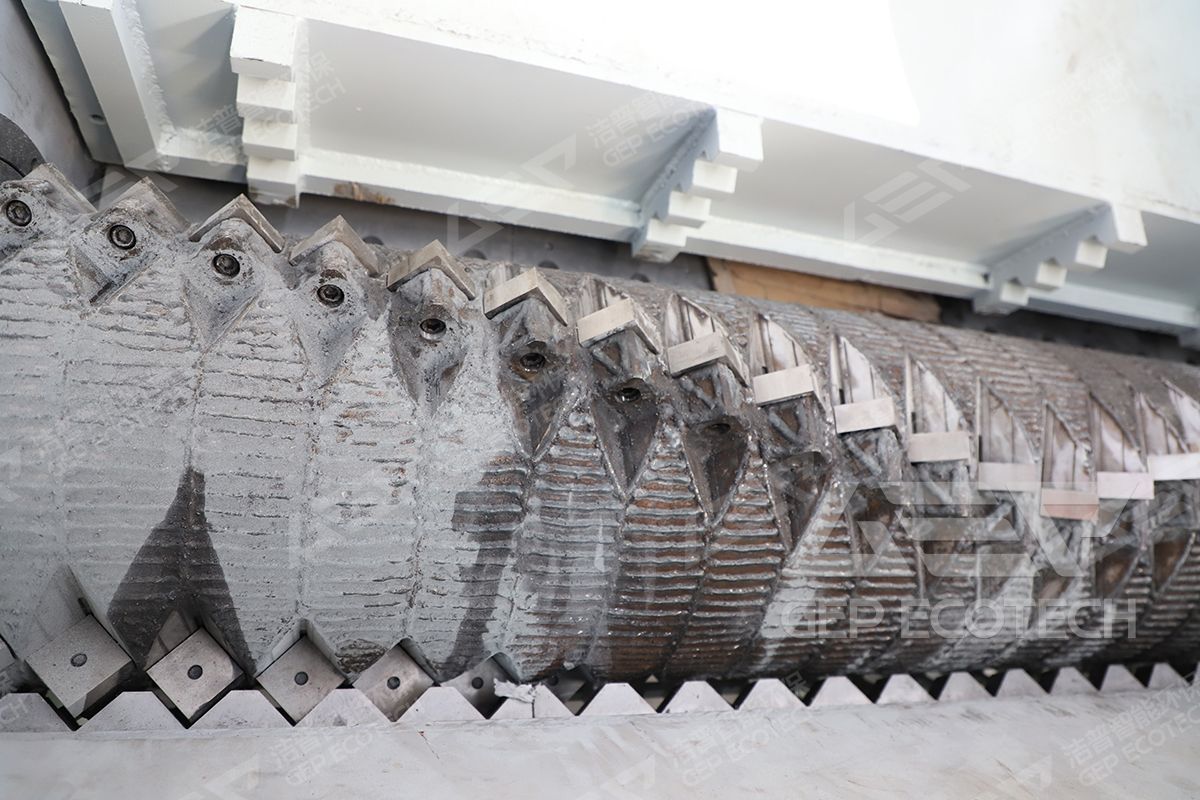

Double Shaft PVC Shredder

A double shaft shredder uses two parallel rotors that rotate in opposite directions to tear, shear, and crush PVC material. It is built to handle tougher, more durable materials and larger volumes.

Key Features:

- Higher Torque and Capacity: Double shaft shredders are more robust and can process thicker, heavier PVC materials, including large PVC pipes and bulky scraps.

- Coarse Shredding: The output is typically coarser than with single shaft shredders, making it suitable for further processing or volume reduction.

- Self-Cleaning Mechanism: The rotating shafts help prevent material blockages, allowing for continuous operation.

Best Applications:

- Large PVC pipes, profiles, and heavy-duty PVC scraps.

- Industrial recycling where high throughput is needed.

Choosing the Right Shredder

The choice between a single shaft and double shaft shredder depends on the nature of the PVC material, the required particle size, and the processing volume. Single shaft shredders are ideal for lighter PVC materials and precise shredding needs, while double shaft shredders excel in high-capacity, tough material processing.

Both options offer distinct advantages in PVC waste management and recycling, helping to reduce waste and contribute to the circular economy. If you have any questions about the selection of PVC shredder equipment, please contact us.