Glass Reinforced Plastic (GRP), also known as fiberglass, is a composite material known for its exceptional strength, durability, and lightweight properties. It is widely used in industries such as automotive, aerospace, and construction. However, recycling GRP poses significant challenges due to its toughness and the presence of glass fibers within the polymer matrix. Specialized shredders are required to efficiently process GRP waste, making recycling feasible and effective.

Features of GRP Shredders

1. Heavy-Duty Construction: Built with robust frames and reinforced components to handle the tough nature of GRP.

2. Advanced Cutting Technology: High-torque motors and durable cutters, often made from hardened steel or carbide, ensure effective shredding.

3. Multi-Stage Shredding: Includes primary and secondary shredding stages to achieve desired particle sizes.

4. Safety Features: Automatic overload protection and safety guards for operator safety.

5. Efficient Material Handling: Advanced feeding systems and output conveyors for smooth operation.

Common GRP Shredder Types

1. Single-Shaft Shredders

- Description: Features a single rotating shaft with sharp blades or knives. Ideal for fine shredding, it reduces large GRP pieces into manageable sizes.

- Applications: Suitable for both primary and secondary shredding stages, offering flexibility and high capacity in processing GRP.

2. Double-Shaft Shredders

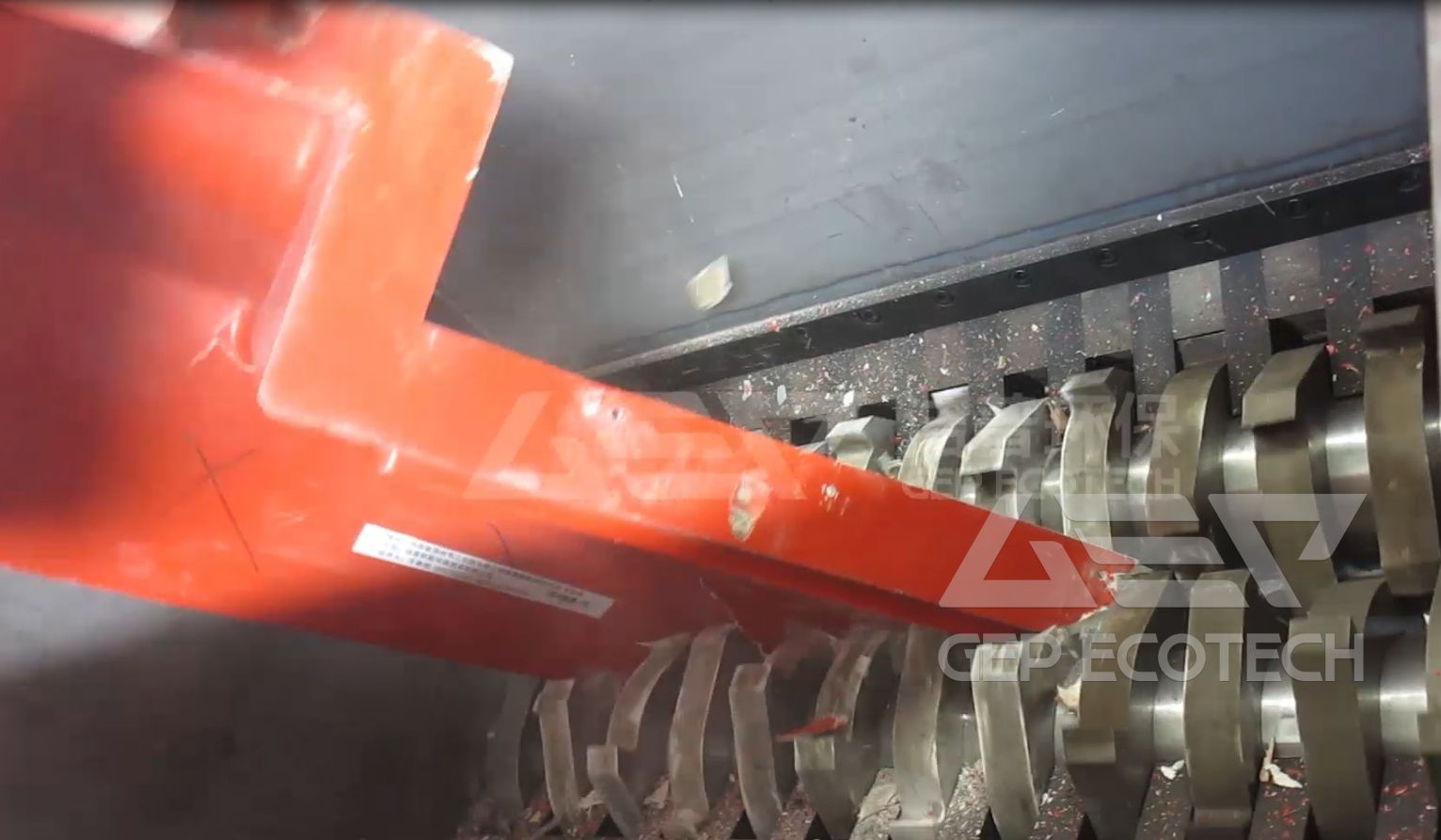

- Description: Equipped with two counter-rotating shafts that grip and shred the material. These shredders offer a more intensive shredding action and are effective for handling tough materials.

- Applications: Suitable for initial size reduction before further processing. Provides efficient shredding of various composite materials.

Case Studies of GRP Shredder

1. Automotive Industry

Case Study: A leading automotive manufacturer utilized a double-shaft shredder to process GRP waste from production lines. The shredder effectively broke down large composite parts into smaller pieces, which were then used in material recovery and recycling processes. This approach improved waste management and supported the company's sustainability goals.

2. Aerospace Industry

Case Study: An aerospace company implemented a plastic shredding line that included a single-shaft shredder and a double-shaft shredder for handling GRP waste from decommissioned aircraft. The shredder's high-torque motor and durable cutters efficiently processed the composite materials, enabling the recovery of valuable glass fibers and polymer resins for reuse in new products.

Specialized shredders for Glass Reinforced Plastic (GRP) are essential for efficiently managing and recycling this challenging material. With features like heavy-duty construction, advanced cutting technology, and efficient material handling, these shredders address the unique demands of GRP waste. The successful implementation of these shredders in industries such as automotive, aerospace, and construction demonstrates their effectiveness in improving recycling efficiency and supporting sustainable practices.