The scientific name of glass fiber reinforced plastics, commonly known as FRP(Fiber Reinforced Plastics), refers to the reinforced plastics with glass fiber as reinforcement and synthetic resin as binder. There are many FRP products, such as FRP tanks, FRP pipes, FRP sand pipes, FRP air ducts, FRP cable ducts, and FRP gratings. Because of its light weight and high strength, FRP is also used in aviation, rocket, spacecraft and fan blades. Since FRP is widely used, it is also necessary to recycle it by physical and chemical methods after it is scrapped.

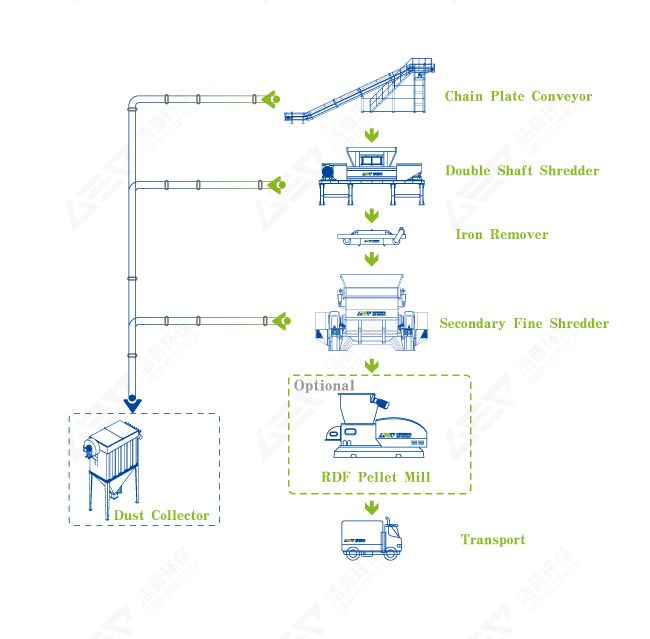

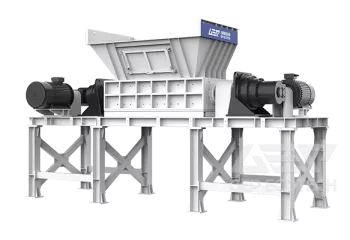

At present, the treatment methods of FRP waste mainly include chemical method and physical method. In the process of both methods, the FRP waste shall be shredded first, so it is very important to select a FRP shredder. If the volume of FRP waste is large and the quantity is large, a double shaft shredder can be used to crush it in large quantities, and then a fine shredder is used for secondary processing. The output particle size can be controlled freely through the screen. The fine shredder of GEP ECOTECH has been upgraded from double rotor fine shredder and single rotor fine shredder to the third generation of European type fine shredder, which has stronger crushing capacity, wider application of materials, and can easily crush waste FRP products of any shape.