Sludge collaborative treatment of kitchen waste refers to the process of combined treatment of sludge and kitchen waste. The complementary role of microorganisms and organic matter in sludge and kitchen waste is utilized to achieve simultaneous and efficient treatment and resource utilization of sludge and kitchen waste.

Anaerobic digestion process should be adopted for sludge collaborative treatment of kitchen waste in urban sewage treatment plants, which includes pre-treatment system, anaerobic digestion system, biogas purification and utilization system, biogas slurry resource utilization and treatment system, and biogas residue resource utilization and treatment system. The pretreatment of the first ring needs to pretreat the sludge and kitchen waste respectively. According to its composition and the subsequent anaerobic digestion process requirements, a reasonable process route should be selected. The process flow should be simple, smooth and environmentally friendly.

Among them, the pretreatment of kitchen waste includes bag breaking, shredding, screening, extrusion dehydration and other processes. The specific requirements are as follows: the particle size of the broken bag shall not be less than 250mm. The primary or secondary screening shall be selected according to the material characteristics, and the primary screening aperture is 40mm-60mm; The first stage screening aperture during two-stage screening is 100mm-120mm, and the second stage screening aperture is 40mm-60mm. When the solid content of kitchen waste is less than 20%, extrusion dehydration process needs to be added. Fine shredding should be set after bag breaking, screening, and squeezing dehydration, and the particle size should be controlled below 40mm-60mm. The conveying equipment connecting various processes can be selected as a belt conveyor or a screw conveyor.

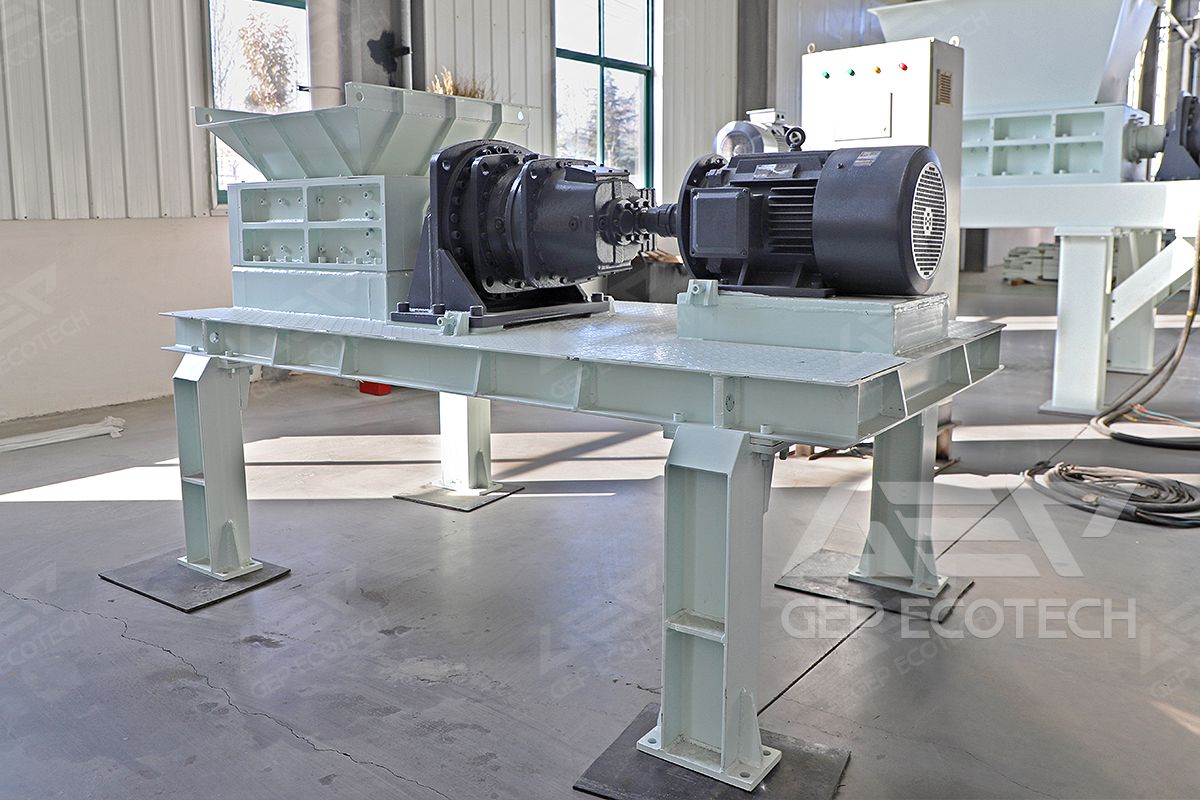

The bag breaker, screening machine, press dehydrator, fine shredder, belt conveyor and screw conveyor mentioned above - all the equipment required for the pretreatment of kitchen waste are available in the equipment warehouse with GEP, and the particle size of the treated materials is also up to the standard. Our fine shredder cutters are made of materials that are resistant to corrosion and abrasion. The cutter box is solid, resistant to impact load, multiple seals and waterproof, the materials are not easy to jam, simple and easy to maintain, etc. All of them are made for the characteristics of kitchen waste. In addition to hardcore equipment, we are also equipped with a powerful GI intelligent monitoring system that can monitor in real time, provide abnormal alarms, remotely diagnose, and analyze data, helping customers achieve intelligent operation and maintenance.

The sludge collaborative disposal of kitchen waste has a good development trend, and GEP will also make continuous efforts for the safe, efficient, energy-saving and low-carbon utilization of sludge and kitchen waste resources and technological progress.