Project Overview:

The construction waste recycling project is located in the suburbs of Moscow, Russia, with a processing capacity of 100 tons per hour. Its purpose is to clean up the demolition waste of buildings in Moscow city and reuse the recycled materials into building aggregates. The project produces four different specifications of finished materials, namely 0-5mm, 5-20mm, 20-40mm, and 40-70mm.

This construction waste recycling line equipment includes crushing system, conveying system, sorting system, screening system, dust reduction system, and intelligent integrated control system. The advantage of this equipment combination is that the process flow is reasonable and smooth, which can improve the utilization rate of garbage resources and impurity separation rate, ensure the quality of recycled aggregates, and extend the service life of related equipment.

Overall, this project not only contributes to environmental protection, but also provides high-quality and renewable building aggregates, creating lasting and stable profits for customers, and has certain promotional value.

Project Highlights:

GEP ECOTECH not only provides a complete set of equipment in the construction waste recycling project, but also participates in the layout design of the entire park's factory and transportation to achieve more efficient and environmentally friendly construction waste treatment.

In terms of technology, we have conducted in-depth research and innovation. We effectively combine crushing and screening, and optimize the combination of crushing, air separation, magnetic separation, screening and other processes to reduce screening before crushing and simplify crushing before screening. Through the multi-stage crushing process, we can crush according to demand step by step, which not only improves the crushing efficiency but also reduces energy consumption, while also extending the service life of the equipment. The multi-stage screening process achieves step-by-step separation, step-by-step reduction, and step-by-step purification, enabling the separation of recycled aggregates, metals, light substances, and unusable materials with different particle sizes. This improves the purity of recycled aggregates and makes their particle size more uniform, providing high-strength and high-quality support for back-end brick making and commercial sand recycling products.

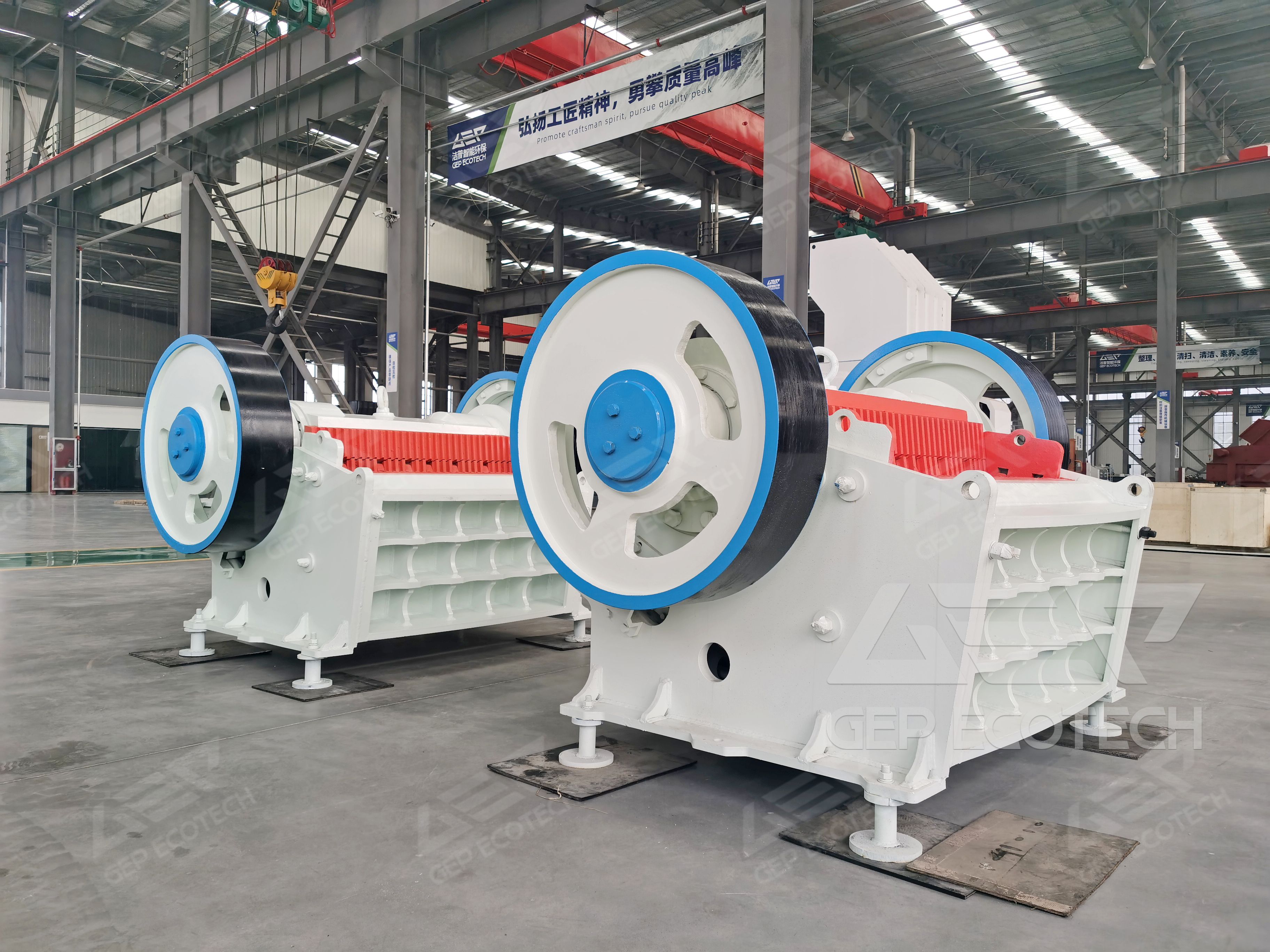

In order to meet the customer's requirements for the powder content in the final product aggregate, our engineers have changed the secondary crushing equipment from a conventional high-speed rotating impact crusher to a low-speed fine jaw crusher in the plan to reduce the production of fine powder in the final product. This modification can better meet the needs of customers, improve product quality and customer satisfaction.

In summary, our company has demonstrated excellent design capabilities and high attention to customer needs in this project. We not only provide efficient process design, but also carefully select equipment and layout planning according to customer needs. These efforts have laid a solid foundation for the successful implementation of the project and also set a good example for future construction waste recycling projects.

Demonstration Significance:

Faced with the increasingly serious problem of construction waste accumulation in Moscow, this project utilizes scientific, efficient, and environmentally friendly disposal methods to convert waste into valuable building aggregates, thereby achieving resource regeneration and recycling. This not only effectively alleviates the environmental pressure in Moscow city, but also creates economic value, and provides a reference example for other cities to deal with similar problems, which helps promote the city's environmental protection and sustainable development.

The significance of solid waste disposal lies in the power of technology and innovative methods, which can transform seemingly unsolvable environmental problems into practical solutions, thus achieving harmonious coexistence of economy, society, and environment.