Particleboard (Particleboard) is a common wood composite board, usually made of wood chips, wood powder and glue. It is widely used in furniture manufacturing, architectural decoration and other applications. However, discarded particle boards need to be effectively treated and recycled to reduce environmental burden and realize resource recycling. Particle board shredders are equipment specially designed for this purpose. There are many factors to consider when choosing a particle board shredder model. This article will discuss in depth how to choose a suitable particle board shredder model.

Factors to consider when choosing a particle board shredder

- Processing capacity: First, consider the number and size of particle boards you need to process. Different models of shredders have different processing capabilities. You need to make sure that the model you choose can meet your production needs. Throughput is usually measured in the number of particle boards processed per hour.

- Power and Horsepower: The power and horsepower of a particle board shredder is closely related to its processing capacity. Larger particle boards or higher processing speeds generally require higher powered shredders. Make sure the model you choose has enough power to handle your particle board.

- Tool type: Shredders are usually equipped with different types of knives such as blades, claws or hammers. The choice of cutter depends on the characteristics of the particle board. For example, thicker particle boards may require stronger knives to handle effectively.

- Grinding particle size: You need to consider the particle size of the shredded particle board you want to achieve. Some shredders are capable of finer shredding, while other models may be better suited for coarser shredding. It is important to choose a model that matches your recycling goals.

- Durability and maintenance: Considering the long-term use of the particle board shredder, it is wise to choose a model that is durable and easy to maintain. This helps reduce maintenance costs and prolongs equipment life.

- Safety and environmental protection: Make sure the selected model complies with safety standards and provides appropriate safety devices and guards. Consider the environmental performance of the shredder, such as whether it is equipped with a dust collection system to reduce particulate matter emissions in the air.

- Cost-effectiveness: It is also important to consider cost-effectiveness comprehensively. When choosing a model, focus not only on purchase cost, but also on operating costs, maintenance costs, and equipment lifespan to ensure you get the ideal profit margin.

Common models of particle board shredders

The following are some common particle board shredder models for your reference:

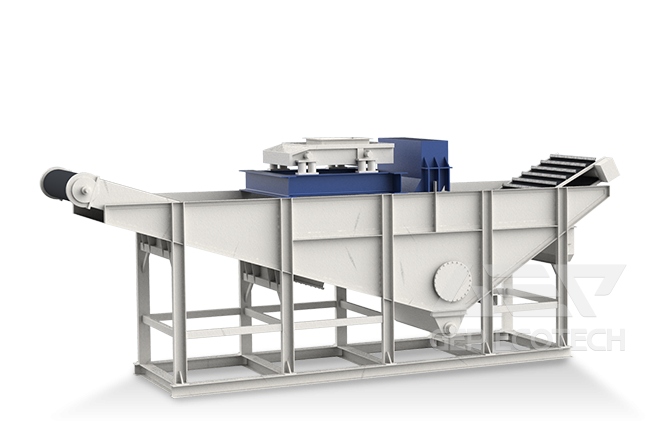

- Single-shaft shredder: suitable for small-scale particle board recycling, with low output and fine output, suitable for customers with fine crushing needs.

- Double-shaft shredder: It has higher output, wide applicability of materials, and does not have too strict requirements on the fineness of the output. This equipment has a high cost performance.

- Four-shaft shredder: suitable for large-scale particle board recycling, with powerful processing capacity and crushing effect, capable of difficult crushing tasks, but the price is relatively expensive.

Choosing the right particle board shredder model is crucial for efficient recycling and processing of waste particle board. The appropriate model should be selected according to the specific production situation and goals. If you are still not sure how to choose, contact GEP and let us give you professional guidance.