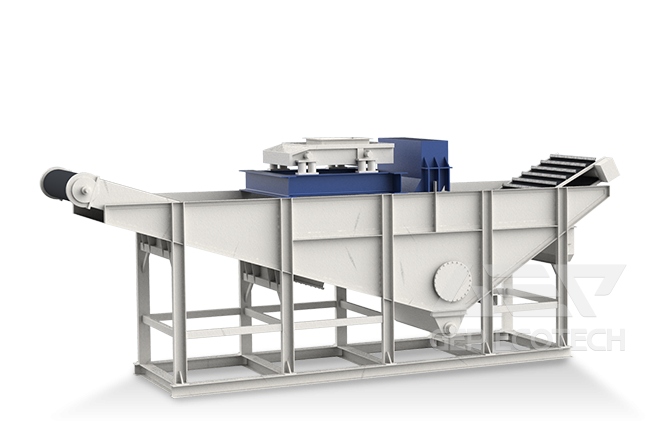

The recycling of OCC waste is an important factor for resource saving and cost-optimized production. Selective recycling of corrugated waste from the manufacturing of your products can become a valuable raw material for more new products. The high-performance OCC waste shredder is the core equipment for processing OCC waste, which has made a great contribution to the economical crushing of OCC waste. Corrugated shredders are specially designed for shredding OCC waste, and the robust drives and rotors can also handle a variety of difficult-to-shred materials. OCC waste shredders are large or small, and can be customized according to output and discharge requirements.

Commonly used OCC waste shredders

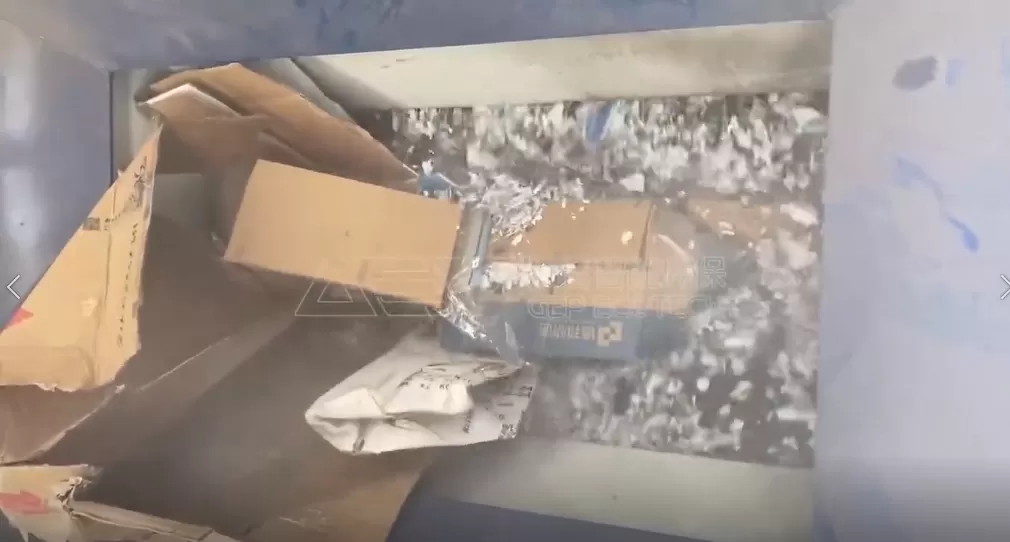

There are two kinds of shredders commonly used to recycle OCC waste, one is the double-shaft shearing shredder, the double-shaft shearing shredder can shred the packaged OCC waste or scattered OCC waste into strips, and then this strips of OCC waste are further processed.

Another commonly used shredder is the single shaft shredder, the single shaft shredder has only one shaft and is usually used as a fine shredder machine, it can shred hard OCC waste into fine size of about 30mm, in this size, the crushed hard OCC waste can be used to make new products or further processed.

The OCC waste shredder not only brings huge economic benefits to customers, but also greatly helps to reduce the waste of wood resources in our country, which can be said to serve multiple purposes. GDI double-shaft shearing shredders, GSD double single shaft shredder and GSS single-shaft fine shredders produced by GEP ECOTECH perform very well in crushing and recycling OCC waste. The configurations of intelligent systems and dust suppression systems can help customers to obtain big profit better while reducing environmental pollution. If you are interested in OCC waste shredder, then come to consult us!