When dealing with mixed waste on construction sites, the coordinated disposal of demolition waste, decoration waste, and bulky waste has become an important issue. These types of waste are often difficult to separate and have different compositions and properties. Therefore, it is particularly important to find a process plan that can simultaneously treat these three types of waste.

At present, there are various process plans and equipment options in the market, but many of them cannot achieve continuous production or have poor quality recycled aggregates. This is mainly because these plans did not fully consider the characteristics of these three types of waste and their differences.

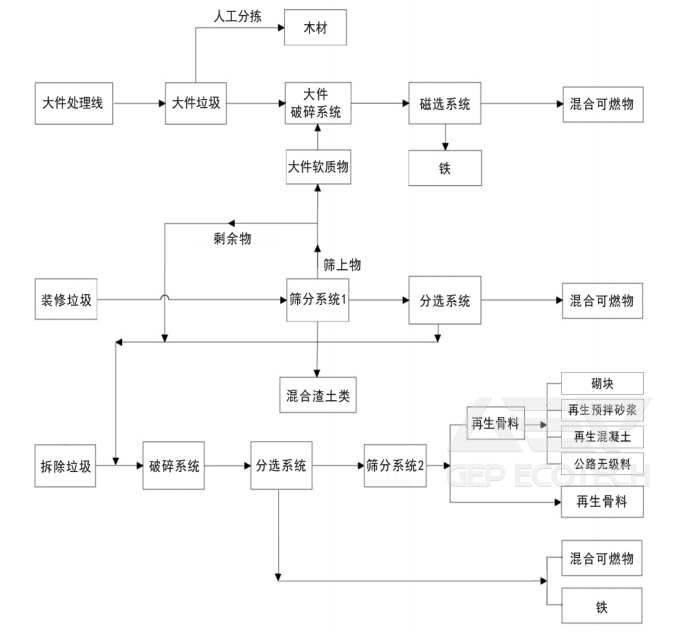

To solve this problem, GEP adopts a brand new process solution, which not only effectively solves the problems of inability to produce continuously or poor quality, but also obtains renewable resources such as iron, recycled aggregates, and mixed combustibles, which are ultimately used for metal smelting, construction material production, and incineration power generation in waste power plants, achieving multiple benefits with one action.

The characteristics of this disposal process are:

- Wide applicability: This process can handle various components of demolition waste, decoration waste, and bulky waste, whether it is hard or soft materials, which can be accepted.

- Reasonable layout: When arranging various equipment, consider the compactness of the space while ensuring sufficient maintenance space and channels between the equipment, which is convenient for subsequent maintenance and management.

- Cost reduction and efficiency improvement: This process can help disposal enterprises reduce comprehensive costs and improve efficiency. Through collaborative processing, we can more effectively utilize resources, reduce energy waste, and also reduce equipment investment and operating costs.

In terms of equipment configuration, it also follows the principles of rationality and practicality, and the quality and performance are superior.

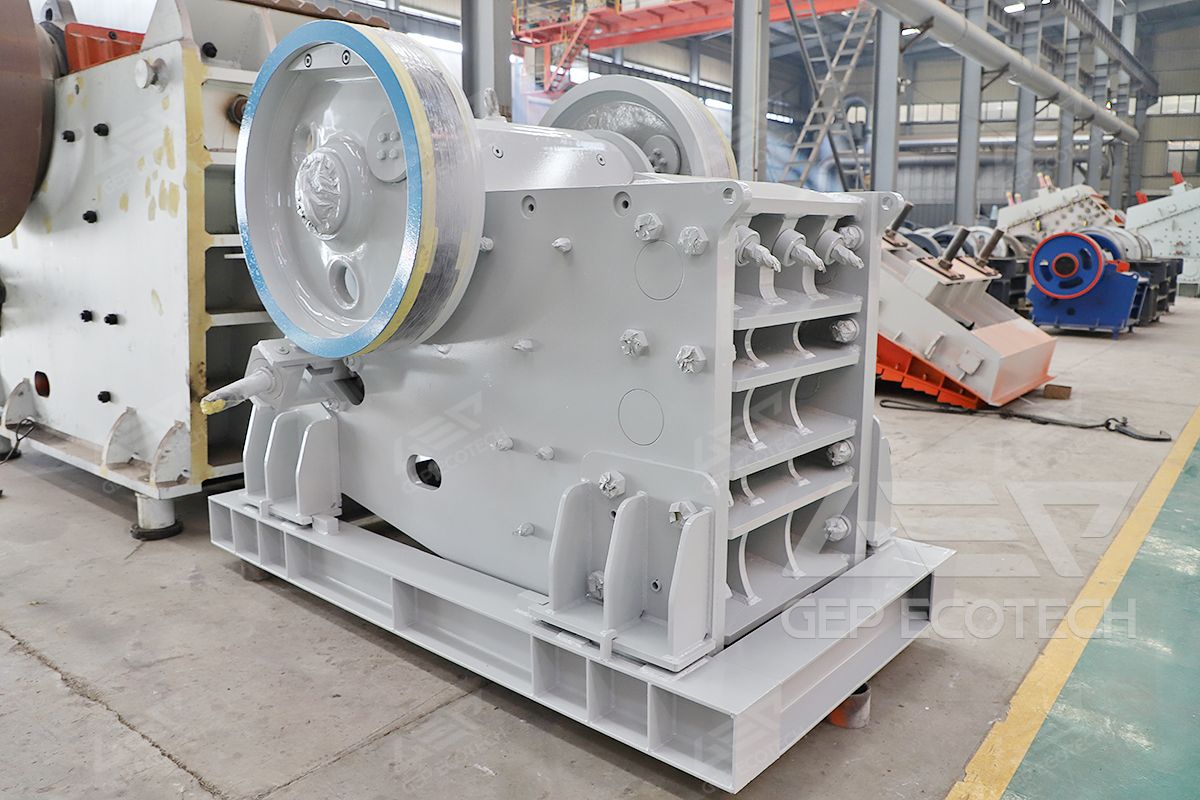

- Crushing system: bulky waste shredder, which can be driven by both hydraulic and electric motors, with strong power and full marks for effectiveness; The jaw crusher adopts a symmetrical V-shaped cavity design, which can feed more materials and have a larger processing capacity; The impact crusher, after optimized design, can effectively avoid the problems of light materials causing jamming, blockage, and entanglement.

- Sorting system: The wind sifter adopts controllable airflow technology, which can effectively separate light and heavy substances with high separation rate. The multi-channel magnetic separator can tightly separate the ferromagnetic substances in the mixed waste, reducing the damage of metals to subsequent equipment and improving the purity of recycled aggregates.

If you have such a need, you can contact GEP to customize your disposal process privately and achieve your environmental protection career.