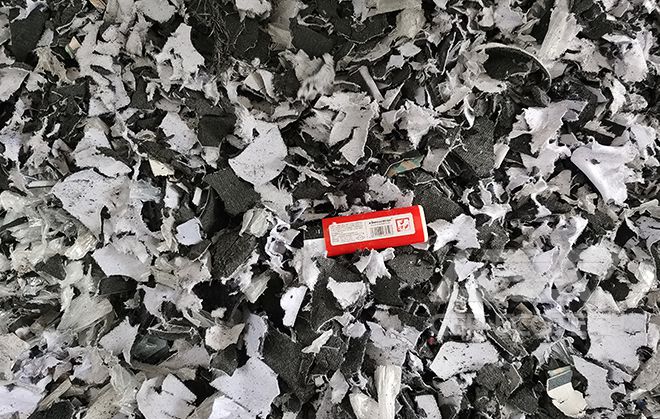

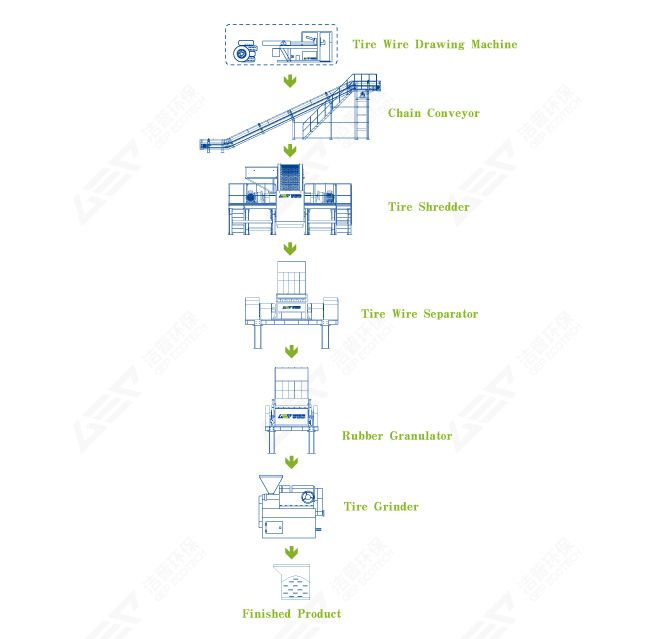

Waste rubber refers to rubber that can no longer be used in normal products. They mainly come from waste tires, rubber hoses, rubber shoes and industrial sundries. In addition, they can be leftover materials or waste products left in the production process of rubber enterprises. Recycling of waste rubbers refers to changing the physical form of rubber or using chemical methods to make them into other rubber products for reuse, such as making life buoys, soles, sports equipment, road laying, tire repair, and generating recycled rubber, rubber powder, rubber asphalt, etc. The purpose of introducing shredder equipment in the recycling process of waste rubbers is to improve the efficiency of the back-end process.

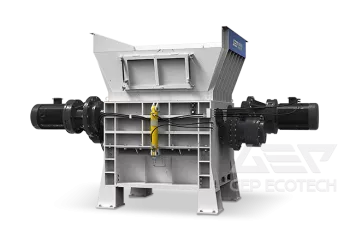

There are many kinds of rubber products, such as tires, conveyor belts, hovercrafts, rubber springs, rubber hoses, adhesive tapes, rubber shoes, life-saving supplies, insulating gloves, raincoats, football, etc. All rubber products that can be put into the feed inlet of waste rubber shredder can be directly shredded without cutting and decomposition. The shredding chamber plate of the waste rubber shredder is thick, firm and durable, and can resist high torque; The cutters are made of alloyed steel, with long service life; The whole machine is controlled by an intelligent control system with high automation and production efficiency, enabling users to economically and effectively recycle large rubber.