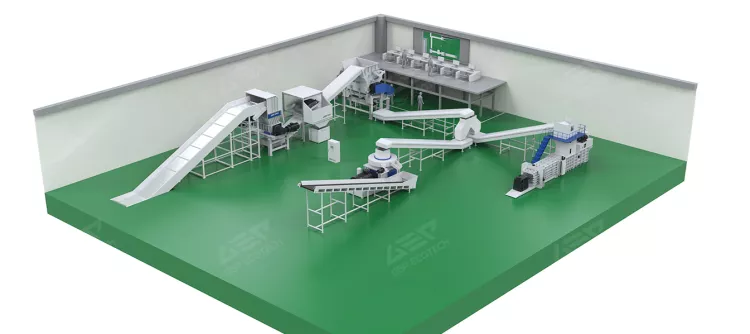

Resourceful Disposal Solution I

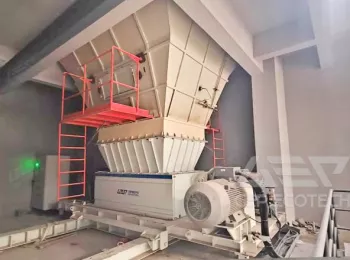

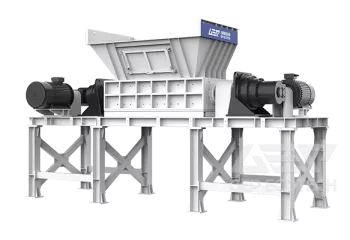

For the general industrial solid waste material composition is relatively single, the solution through the double-shaft shredder + fine shredder of the two-stage shredding, and magnetic separator of the two sorting treatment, by two-way belt will be combustible materials sent to the RDF forming machine to make fuel rods directly sold to the thermal power plant for fuel, but also directly transported to the hydraulic baler compressed baling outside the sale, both to dispose of waste, but also to earn a profit.

Benefits of GEP Ecotech I&C Solid Waste Resourceful Disposal Solution

- Simple process of the whole line, good shredding and sorting effect, all materials are used to their full potential.

- A high degree of automation in the production line, which is safe, environmentally friendly, effortless, and labor-saving in operation.

- All equipment is self-developed by GEP ECOTECH, with guaranteed quality, performance, and efficiency.

GEP Ecotech can design specific disposal solutions for different materials and treatment purposes; we also have thermal imaging detection and fire alarm systems for production lines to ensure safe production..