According to data from the China Material Recycling Association, in 2022, the total production of plastic products in China was 63 million tons, of which 18.9 million tons were recycled, accounting for 30%. The recycling capacity is significantly insufficient, and a large amount of waste plastic has not been effectively utilized. Correspondingly, before the implementation of the “Ban on Waste” in 2017, China imported millions of tons of waste plastics annually for industrial production. Even in 2017, there were still 5.83 million tons of imported waste plastics, indicating the high demand for plastics in China. From this, it can be seen that recycled plastics will undoubtedly face a situation of supply shortage for a long time, which can also be seen from the continuously rising price of PET plastics.

At the same time, as the “dual carbon” target approaches, the control of carbon emissions is increasing, and carbon emissions and carbon emission trading have also created a huge demand market for alternative fuels. Waste plastics, as fuels with high calorific value, naturally become a driving force for alternative fuels.

Waste plastics come from a wide range of sources, including industrial waste, municipal solid waste (MSW), agricultural waste, and medical waste. The sources of waste plastics in industrial waste sources are relatively concentrated, and the quality of waste plastics is better, making them more suitable for direct recycling as raw materials after shredding and cleaning; Due to the complex composition and difficulty in recycling, plastics from other sources of waste are more suitable for mixing with combustible materials such as waste textiles and paper to form alternative fuels for incineration and reuse.

According to the difference in utilization methods between the two, GEP ECOTECH has designed corresponding utilization plans.

Waste Plastics → Recycled Raw Materials

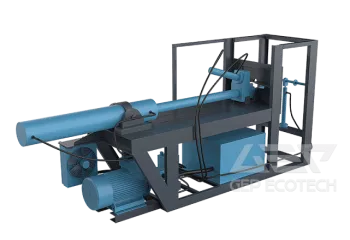

PP, PE, HDPE and other plastic waste can be shredded through two-stage shredding using a double shaft shredder and a European version single shaft fine shredder, as well as automatic iron removal using a magnetic separator, to obtain pure recycled raw materials and achieve resource recycling.

This process is simple and efficient, adopting pure mechanical physical shredding to maintain the original plastic quality during discharge, making it convenient for downstream direct processing into various plastic products.

Waste Plastics → Alternative Fuels

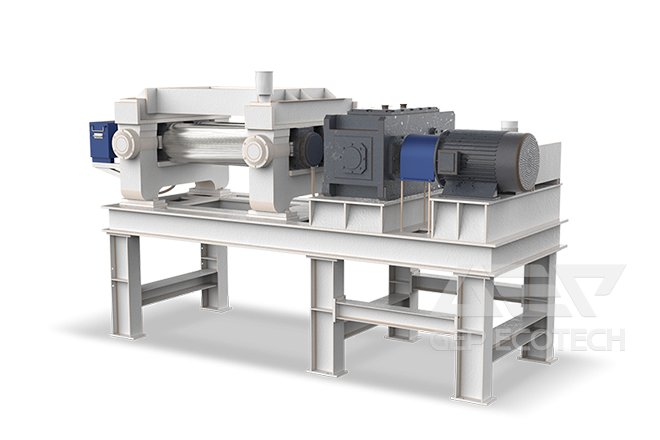

Due to the mixed materials, this plan is equipped with two-stage shredding equipment, as well as sorting equipment such as trommel screen, wind sifter, and magnetic separator. After shredding and sorting, combustible low value recyclable materials such as plastics, cardboard, and fabrics are baled and compressed in hydraulic balers, and sold as RDF alternative fuels.

Although this process is complex, with the support of the GI intelligent monitoring system, the operation process is fully automated and the labor cost is low; The main source of raw materials comes from MSW, various mixed waste, etc., with low acquisition costs and high returns.

From the release of the “Opinions on Accelerating the Construction of a Waste Recycling System” by the General Office of the State Council in early February, to the inclusion of “Promoting the Development of Waste Recycling Industry” in the government work report during the Two Sessions in March, all of which demonstrate the government's high attention to waste recycling. As an important part of the system, waste plastics will have broad development prospects whether converted into recycled raw materials or used as alternative fuels. Let's wait and see!