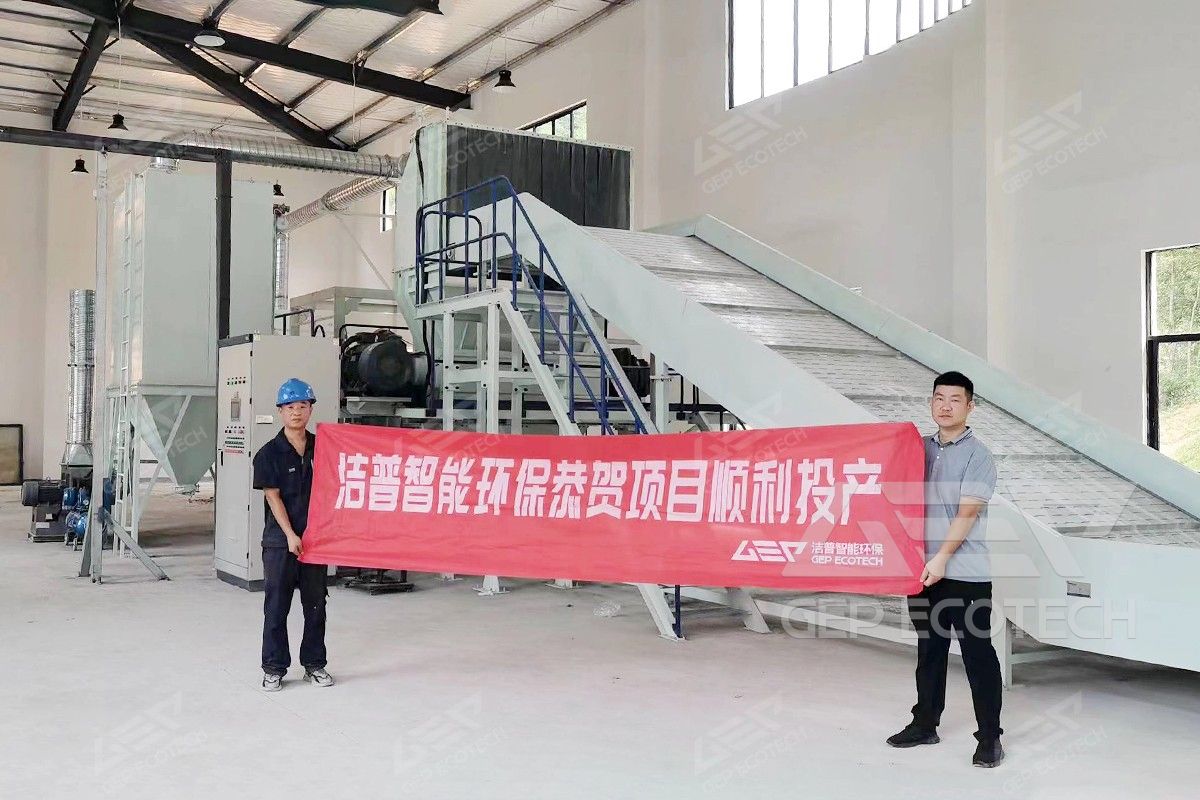

The ignition ceremony for the No.1 boiler of a sludge and industrial solid waste resource utilization project provided by GEP ECOTECH for industrial solid waste disposal equipment has been successfully held recently; The insulation paper shredding production line, with the GSS series European single rotor fine shredder as the core equipment of GEP ECOTECH, has also been orderly put into production in a certain city in northwest China; GEP ECOTECH's European construction waste disposal project and North American waste metal disposal project have also been completed and successfully put into operation... GEP ECOTECH, which has blossomed in many places, is still making great progress in its most skilled bulky waste disposal project. However, new projects have been completed in the past few days.

The classic configuration of bulky waste shredding system, inlet and outlet conveying system, magnetic separation iron removal system, pulse dust removal system, and intelligent control system is timeless. The main reasons why it stands firm in the bulky waste disposal market are its ultra-high crushing efficiency, ultra large capacity reduction effect, ultra stable operating state, ultra simple maintenance method, and ultra long service life.

Of course, in the current trend of alternative fuels, GEP ECOTECH has also launched the bulky waste alternative fuel preparation system in line with the times.

The wood, plastic, sponge, fabric and other combustible materials in bulky waste components are all very good. After undergoing automatic crushing, automatic iron removal, automatic packaging and other processes, the alternative fuels made can be directly transported to the garbage power plant for incineration. This system is very suitable for small bulky waste resource disposal centers and waste transfer stations. Due to the fully enclosed design of the entire system and the equipped pulse dust removal system with high dust removal efficiency, there is no need to worry about the impact on the lives of surrounding residents.

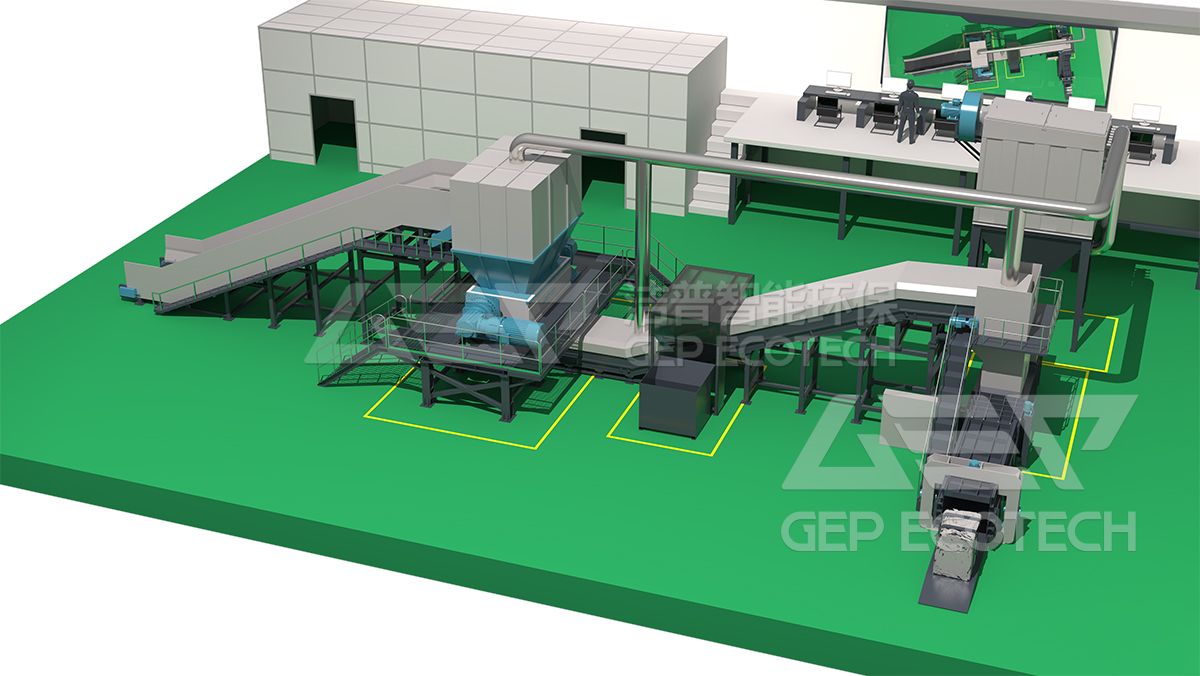

If it is a large-scale comprehensive garbage classification and treatment center, or a professional alternative fuel manufacturer, then the following system will be more suitable.

The process of multi-stage shredding, multi-stage sorting, and granulation forming can achieve the effect of rapid capacity reduction, effective classification, and 100% utilization of resources, completely solving the problem of no place to place bulky waste that troubles the environmental sanitation system for a long time. Its ultimate product, alternative fuel, has many uses. It can be sold to cement plants to help them meet carbon standards, or to household waste incineration plants to alleviate their hunger. It can also be sold to the "main force" heating companies in northern cities to generate excess heat.

GEP ECOTECH is committed to providing customers with more efficient, environmentally friendly, and valuable solid waste disposal solutions on the path of continuous innovation and progress. Facing the future, GEP ECOTECH will continue to lead development with technology, drive progress with innovation, and contribute to the global environmental protection cause.