The feeding method chosen for the solid waste shredding process depends on the type and nature of the solid waste being processed, as well as the specific shredding equipment used. There are several feeding methods commonly used in the solid waste shredding process:

- Batch feeding: It is the use of a grab or loader to pour a large amount of material into the shredder hopper. Batch feeding is common in household appliance destruction, building demolition work, or packaging material handling. Although batch feeding is simple and direct, the efficiency is relatively low. If the size of the shredder blade box is not suitable and bulk feeding is used, it may cause material bridging blockage or accept more than the shredding capacity at once.

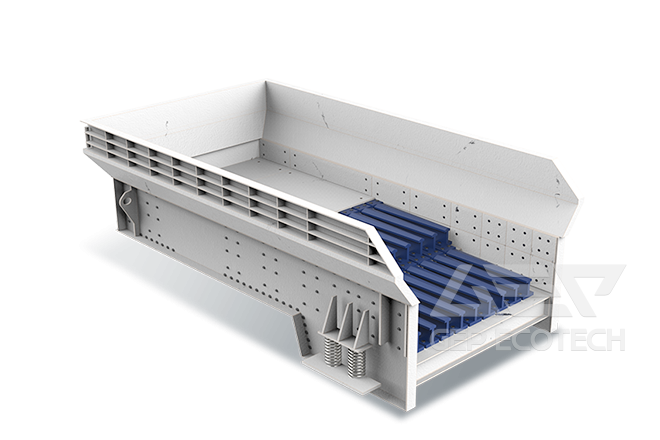

- Measurement feeding: Refers to the feeding of materials into the shredder hopper at a stable and controlled flow rate through a conveyor. If the material can be metered and fed, the shredder can monitor its feed rate and more effectively adjust the production line's mixing speed. The result of measuring the feed is that there are fewer reversals or shutdowns.

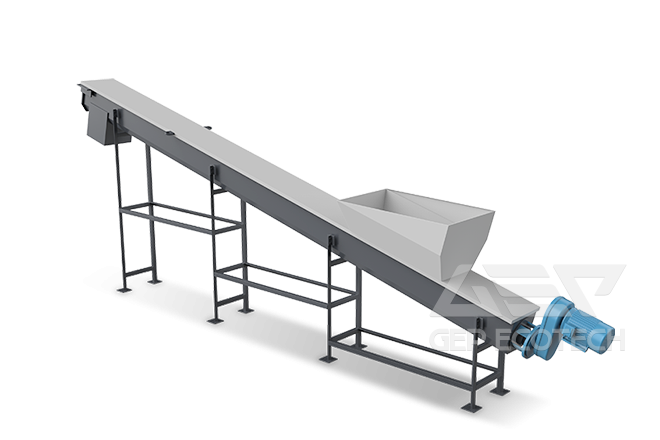

In terms of conveyor selection, belt conveyor and chain conveyor are both good choices. The conveyor belt of the belt conveyor generally adopts rubber belts. According to the characteristics of different materials, rubber, silicone, PVC, PU, heat resistant, cold resistant, acid alkali resistant, oil resistant, etc. can be selected; The conveyor belt of the chain conveyor is generally made of carbon steel, stainless steel, and thermoplastic chain materials. The belt conveyor utilizes the friction between the driving drum and the conveyor belt to transmit power, achieving material transportation. It can be used for horizontal, inclined upward, and inclined downward material transportation; The chain conveyor uses a series of chains fixed to the traction chain to provide traction, and uses metal plates as carriers to guide the material to be transported in a horizontal or oblique direction. Belt conveyors are more suitable for lightweight transportation, with low noise and low cost; Chain conveyor is more suitable for heavy-duty transportation and has a long service life.

GEP is a professional supplier of intelligent solid waste shredding equipment and solid waste production line system solutions. We usually recommend suitable shredders, conveyors, and feeding methods to customers based on factors such as material characteristics, shredder working environment, and customer investment amount, in order to maximize the efficiency of all equipment in the production line and reduce customer investment.