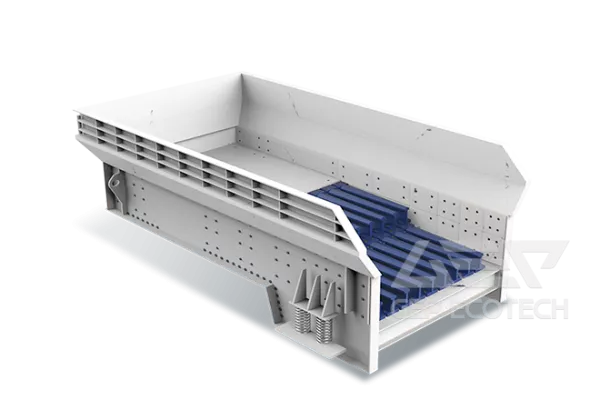

The vibrating feeder is mainly composed of the vibration frame, spring, vibrator, motor vibration frame, and motor, and is widely used in industries such as metallurgy, mining, coal, building materials, chemical, power, solid waste treatment, etc.

The vibrating exciter of the vibrating feeder consists of two eccentric shafts at specific positions that mesh with gears. It is driven by the motor to rotate the two eccentric shafts, generating a huge synthetic linear excitation force, which forces the machine body to vibrate forcefully on the support spring. The material is then driven by this vibration to slide and throw on the material chute, thereby moving the material forward to achieve the purpose of feeding. When the material passes through the screen bars on the chute, smaller materials can fall through the gaps between every two screen bars and do not go through the next shredding process, achieving the effect of screening.