Aluminium plates are widely used in industries such as automotive, aerospace, construction, and packaging due to their lightweight, durability, and corrosion resistance. However, recycling or repurposing aluminium plates often requires reducing them into smaller, manageable pieces. This is where a shredding machine specifically designed for aluminium plates comes into play.

Not all shredders are suitable for processing aluminium plates due to the material's toughness and density. The following types of shredding machines are commonly used for this purpose:

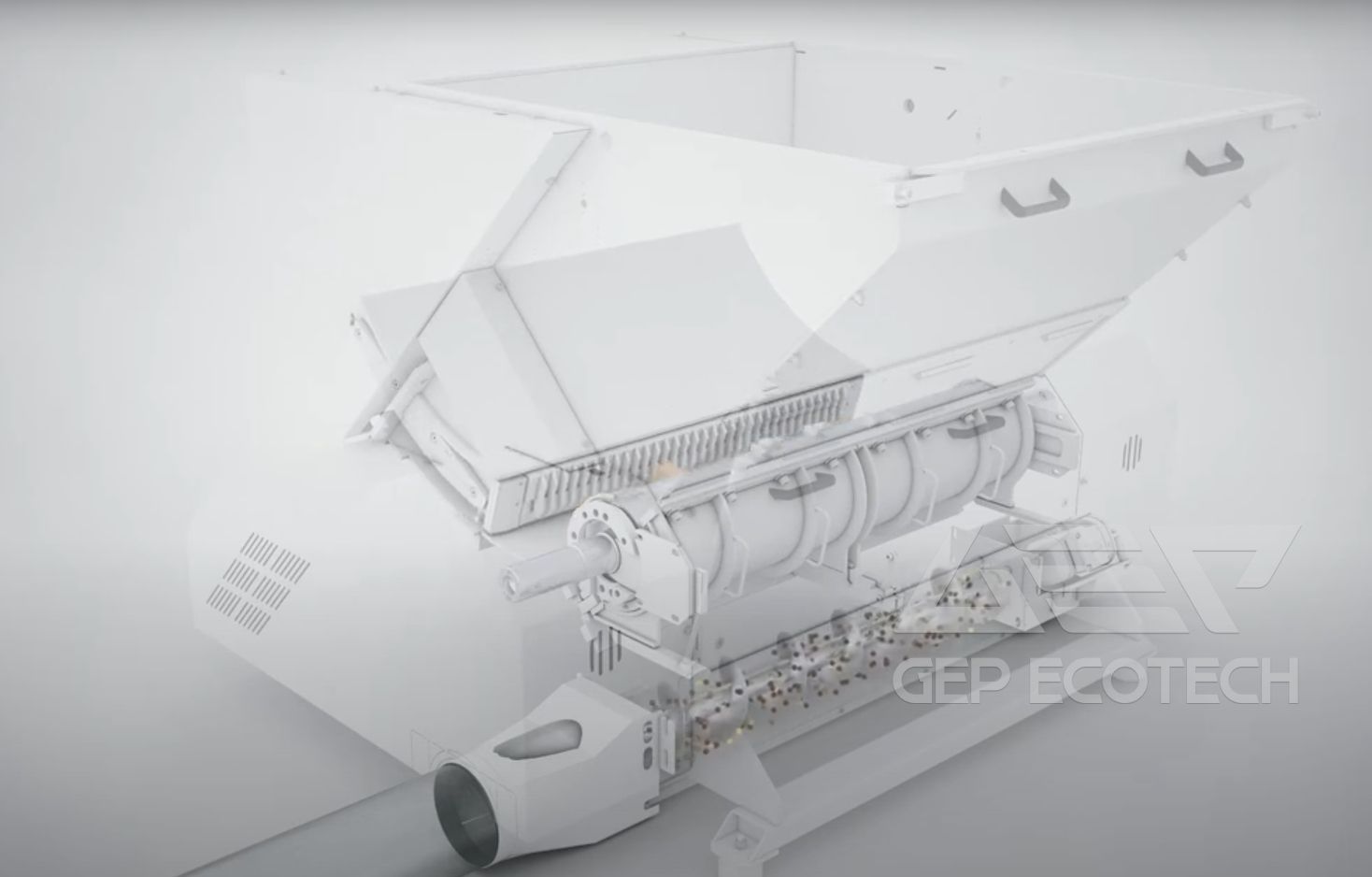

2-Shaft Shredders

- These shredders feature two counter-rotating shafts with cutting blades that tear and shear aluminium plates into smaller pieces.

- Ideal for processing thick and heavy aluminium plates.

- Known for their durability and ability to handle high torque requirements.

4-Shaft Shredders

- Equipped with four shafts, these machines provide additional cutting power and are suitable for processing larger volumes of aluminium plates.

- They offer finer output sizes compared to 2-shaft shredders.

Single-Shaft Shredders

- These shredders use a single rotating shaft with blades to cut through aluminium plates.

- Suitable for thinner aluminium plates or smaller-scale operations.

Aluminum plate shredding is a crucial step in the recycling process, and the right shredding machine depends on factors such as the thickness of the aluminum, the volume of material to be processed, and the desired particle size.

Understanding the features, advantages, and limitations of each type of shredding machine will help businesses select the best equipment for efficiently processing aluminum plates and contributing to sustainable recycling practices. If you have any questions about the model selection of aluminum plate shredder, please contact us to provide you with professional answers.