Project Overview:

A new resource recycling and utilization center will be built locally, which integrates food and kitchen disposal, other waste sorting and crushing systems, RDF forming systems, bulky waste, garden waste pretreatment systems, recyclable material sorting systems, leachate treatment, and intelligent control centers. The center will be used for the resource recycling and utilization of various types of solid waste in the surrounding area, while also achieving commercialization.

Project Highlights:

There are many types of materials that need to be disposed of in the project, and the site is limited. When designing the process, solid mixed waste, bulky and garden waste are integrated into a comprehensive disposal line based on local factors such as garbage composition, classification level, transportation mode, and site. Through the overall monitoring and linkage of the control system, corresponding disposal modes can be set according to the different materials, fully considering the characteristics and disposal needs of different materials, Control the closing or opening of required crushing equipment, screening equipment, air separation equipment, forming equipment, packaging equipment, etc., to form different disposal processes, achieving the goal of using a comprehensive disposal line to dispose of various types of solid waste.

The comprehensive disposal line flexibly adopts a bypass auxiliary system based on the common points of different materials in the fields of crushing and sorting, achieving the sharing of different disposal process equipment. This not only effectively saves land area, but also fully utilizes the quality advantages and disposal capabilities of the equipment, avoids the repeated purchase of similar equipment, and effectively reduces the labor and downtime costs of the entire line operation.

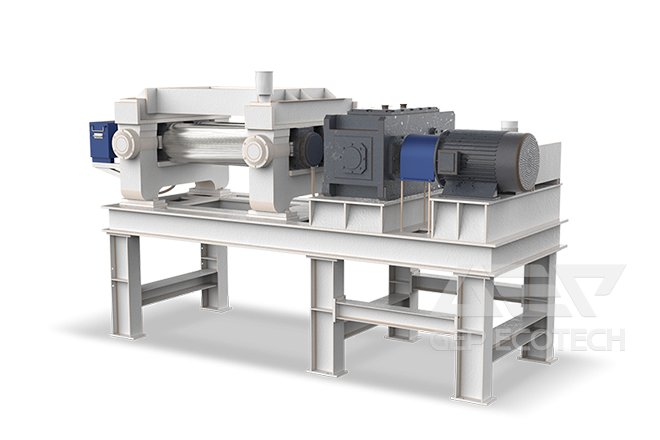

The stable operation of the entire disposal line benefits not only from the high-quality materials and processing technology of GEP equipment, which can meet long-term continuous stable operations, but also relies on the monitoring and linkage functions of the GEP GI intelligent control system, providing a "smart brain" for the operation of the entire line. Moreover, the GI intelligent control system can detect abnormal operation in a timely manner and provide problem prediction prompts and alarms based on data such as temperature, current, oil pressure, and operating time of different equipment core components. It can also automatically identify and complete the process when reverse feeding is needed in case of material blockage or oil lubrication is needed.

Demonstration Significance:

In the current situation where garbage classification work is not yet perfect and mixed transportation of garbage is widespread, there is a clear potential demand for the comprehensive disposal of mixed garbage and various solid waste. In addition, the lack of funds among property owners has put forward higher requirements for solid waste disposal processes.

Most of the existing disposal processes in the market are too single, resulting in some places having to build multiple disposal lines to dispose of different types of solid waste. The phenomenon of repeated purchase of similar equipment and long-term idle of some production lines due to insufficient materials is common.

Based on the above situation, a comprehensive disposal line that can achieve equipment linkage and multi process combination not only saves land area and labor, but also effectively avoids the problem of repeated purchase and idle equipment, and can save a lot of later operating costs through energy conservation and consumption reduction.

The use of equipment in the comprehensive disposal line is becoming more frequent, and higher requirements are placed on the quality of equipment. This also helps to improve the situation where solid waste disposal equipment is gradually falling into the dilemma of low price and low quality competition. From the source of use, the emphasis on equipment quality is constantly increasing, promoting equipment manufacturing enterprises to continuously improve product quality and processing technology, thereby achieving a virtuous cycle of technological innovation and high-end quality guiding industry development.