It has become a consensus that Construction waste can be recycled. But not all Construction waste can be turned into treasure. The construction waste that can be recycled mainly refers to the waste concrete, demolition waste and decoration waste generated during the construction, reconstruction, expansion, repair or demolition of construction projects and the process of house decoration, excluding the Construction waste that has been inspected and identified as hazardous waste, as well as the engineering waste and mud that enter the consumption site for consumption.

The particles of construction waste after sorting, mechanical crushing and screening are commonly referred to as recycled aggregates; The recycled aggregate used in the field of road engineering is called recycled aggregate. Using recycled bone (aggregate) instead of a certain proportion of natural aggregate to make building materials products will realize the "magnificent transformation" from Construction waste to building materials products, which will be used in housing construction, municipal engineering and road engineering.

From construction waste to recycled bone (aggregate) to building materials products, the core link is crushing. Fixed crushing equipment can be used, and mobile crushing equipment increasingly favored by customers can also be used.

Fixed crushing equipment mainly includes jaw crusher, impact crusher, cone crusher and vertical shaft impact crusher. If there are many plastics, wood, paper, sponges and fabrics mixed in Construction waste, double shaft shredder must be used. The jaw crusher (ZL201710380803.8) and the dual shaft shredder (ZL202011009400.0) are both patented products of GEP. They have high efficiency, low energy consumption, easy operation, easy maintenance, long service life, low operating costs, and high automation, which are common features of both. They are also suitable for all GEP manufacturing.

Jaw crusher: symmetrical V-shaped crushing chamber, strong crushing, high output

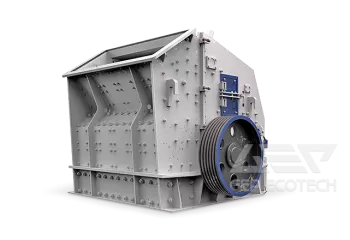

Impact crusher: heavy-duty rotor+enlarged feed inlet, high crushing efficiency

Cone crusher: principle of laminated crushing, more sufficient mutual crushing and self crushing

Vertical shaft impact crusher: crushing+sand making+shaping, standard configuration for high-quality aggregates

Double-Shaft Shredder: alloy steel blade material, finely processed, durable

Mobile crushing equipment is mainly divided into tire type mobile crushing stations and crawler type mobile crushing stations. It is flexible and suitable for a wider range of fields, can be processed locally, saves infrastructure costs, and has high asset value preservation.

According to the market forecast, the market size of China's Construction waste industry is expected to reach 4.4 trillion yuan this year, with a growth rate of about 8%; Infrastructure construction in various regions has also been in full swing after three years of dormancy, resulting in a huge consumption of building materials and products; Upstream resources are abundant, and downstream demand is high. Choosing equipment manufactured by reliable manufacturers like GEP in the midstream is a reliable winner!