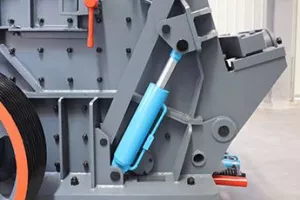

The impact crusher can crush concrete, asphalt, bricks, stones, glass and other waste materials of construction and demolition waste to a recyclable size. It is an indispensable equipment for construction and demolition waste disposal and recycled aggregate production. The impact crusher is specially optimized for the difficulties encountered in the demolition and garbage recycling, which allows it to have excellent performance during crushing. GEP Ecotech's impact crusher is used as a quarry, construction waste disposal center and demolition site, etc.

The impact crusher uses horizontal and high-speed moving rotors to crush materials, which can help the producer to obtain a fine-grained and evenly distributed product. Impact crushers are widely used in the production of construction aggregates and crushing construction and demolition waste. GEP Ecotech's impact crusher uses high-strength materials, which greatly improves the life of the whole machine and vulnerable parts.

Impact crushers use impact to reduce the size of the material and are suitable for handling a variety of low to medium hardness materials, usually used as primary or secondary crushing. When the impact crusher is in operation, the motor drives the rotor to rotate at high speed and the material enters and falls onto the rotor, which strikes the material at high speed and the liner in the crushing chamber is crushed again. The material produced by the impact crusher has fine particles and is nearly cubic in shape.