Consumers around the world consume an average of 1 million beverage bottles per minute, and 8 million tons of plastic waste flows into the ocean every year. These discarded plastic bottles engulf the life of the ocean and threaten human health. Bottled water and bottled beverages are convenient for the public. However, the natural decomposition time of plastics is more than 400 years. How to deal with the used plastic bottles? This has become a worldwide problem.

It is estimated that by 2021, the global consumption of plastic bottles will reach 500 billion a year, far exceeding the efficiency of recycling, and the seawater, coastal and other natural environments are facing the danger of plastic pollution. Plastic bottles are mainly made of materials such as polyethylene or polypropylene and added with various organic solvents. Recycling and recycling plastic packaging not only reduces environmental pollution, but also achieves carbon emission reductions that can fully charge 394 billion mobile phones or allow a car to travel 12.2 billion kilometers.

Statistics show that with the development of the economy and the improvement of living standards, the number of beverage packaging in China has surged. The annual consumption of plastic bottles exceeds 5 million tons, about 200 billion (about 143 per capita), ranking first in the world. Chinese people consume 200 billion and more than 5 million tons of plastic beverage bottles a year, most of which are recycled.

The polyester used in plastic bottles and the polyester fabrics and polyester fabrics mentioned in the textile industry are all the same raw materials. About 80% of the plastic bottles will be used in the textile industry after recycling, and the industry calls them recycled fibers. Plastic recycled textiles are lighter, have better water absorption than cotton, and can save up to 30% in energy during the manufacturing process. At the same time reduce the consumption of oil and water resources.

In fact, at present, in the face of increasingly severe environmental and energy pressures, the implementation of sustainable development strategies and the implementation of the green development concept has become one of the important topics of the global economy. In this big wave, recycled chemical fiber (recycled chemical fiber) has the characteristics of “turning waste into treasure”, has the characteristics of green, recycling, sustainable, and can reduce the consumption of petrochemical resources. Recognized by the international market, it is standing on a new “window” and welcoming new opportunities.

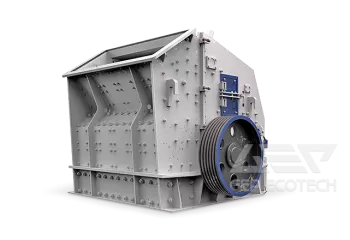

In the plastic recycling center, the plastic scrap in production is generally broken, and after drawing, it is drawn into chemical fiber and re-injected into the production line for further use. Because of this, crushers and granulators are essential equipment in the plastics industry.

Plastic bottle crusher

The material is mainly broken by the principle of mutual shearing and tearing between two relatively rotating cutters. Its function is to break up waste plastics, defective products and waste plastic products into small particles, which are easy to recycle and reuse and reprocessed into plastic products.

Jiepu Intelligent Plastic Crusher is a kind of solid waste volume reduction and shredding equipment used to tear plastic, film products or materials, which is beneficial to plastic recycling and recycling of plastic particles. Processing materials include mineral water bottles, PET bottles, oil bottles, gasoline bottles, plastic drums, films, agricultural films, tons of bags, tons of bags, nozzles, plastic heads and so on.

A plastic bottle can be divided into three kinds of materials, the bottle cap belongs to PE, the bottle body belongs to PET, the label on the bottle belongs to the raw material of PVC, the PET processing workshop separates and classifies, and after removing the sundries, it is broken, after three times of breaking. Rinse and then divide into PE, PVC, PET three materials for drying, and finally become a plastic sheet, plastic sheet material can be made into chemical fiber for making clothes, can be reduced to the original bottle for reuse, can also be made into a disposable meal Box and so on.

The recycling of chemical fiber industry is an integral part of the green development of the textile industry, and it is one of the main directions for the comprehensive utilization of waste polyester bottles and waste textiles. Through the adoption of new technologies, new processes and new equipment, the economies of scale of the industry are gradually emerging, the achievements of scientific and technological innovation are increasing, and the average energy consumption and water consumption are significantly reduced.