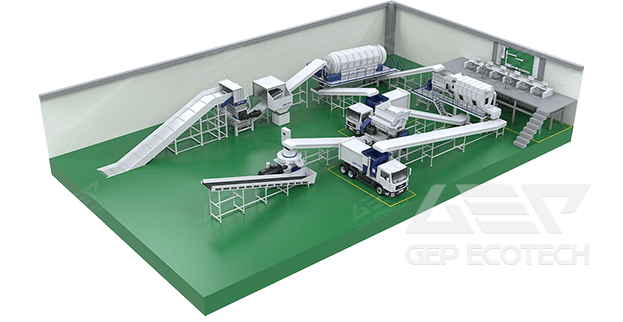

The shredding waste disposal system supplied by GEP ECOTECH can directly feed the whole vehicle, saving front-end transportation costs, saving time and labor, and reducing labor costs. The layout plan can be designed according to the site, and the process is reasonable. Closed dust removal can reduce pollution and improve the working environment.

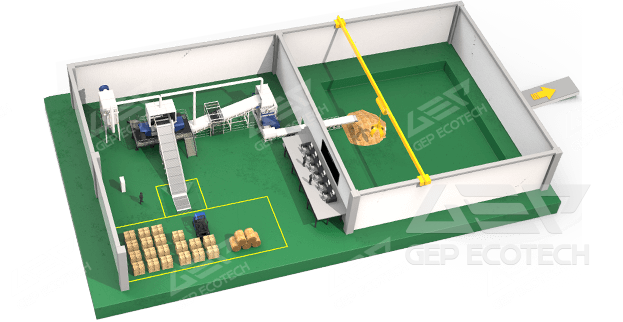

Waste paperPaper manufacturing, pulp manufacturing, paper processing product manufacturing, printing and publishing, binding business, as well as waste paper generated during construction demolition processes.Waste paper treatment (recycling) methods1.…

Waste plasticSolid and liquid waste plastics such as synthetic resin waste, synthetic rubber, and synthetic fiber waste generated in industrial and commercial activities, as well as synthetic leather waste and residual rubber, also belong to waste…

Cement production is an industry that consumes large amounts of energy and resources. Subject to the rate of economic development, public infrastructure construction and the downturn in the real estate and other industries with immediate needs, the…

GEP Ecotech has extensive experience in providing shredding, fuel blending, destruction and recycling solutions for the hazardous waste disposal industry. We design one or more efficient shredders depending on the material, quickly reducing the material…

Waste tires are known as "black gold mines" and are of great recycling value. For example, direct retreading and reuse, recycling steel wire to make steel, rubber grinding to make rubber powder, pyrolysis to make oil, cement rotary kiln or power station…

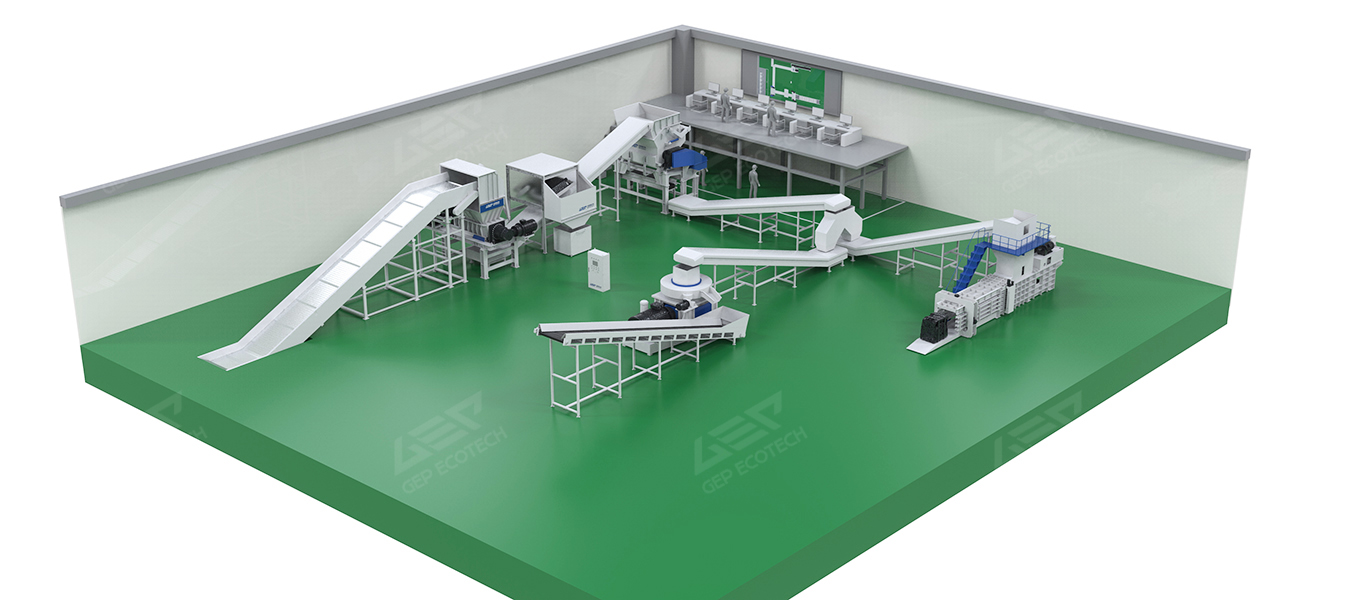

Solid waste is fed into the shredding plant using a belt or feeder to reduce the material to the required size. For most materials, a twin or four-shaft shredder can be used to process the material to the target size in one pass; for piles or bales, a…

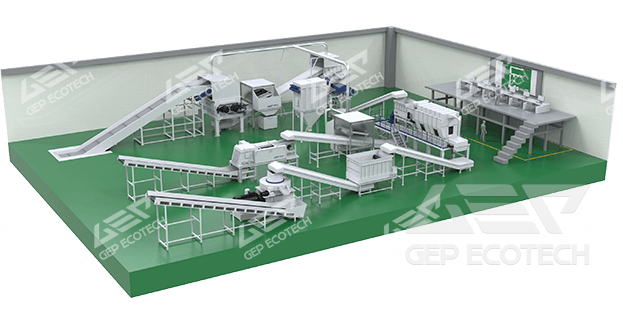

MSW disposal involves volume reduction and sorting. The waste is reduced for further processing using different levels of shredders, then sorting equipment is used to separate the valuable materials from the waste. The higher calorific value materials…

The disposal of industrial waste revolves around volume reduction, reuse and recycling. Depending on the characteristics of the material, a multi-stage shredder or crusher is used to reduce the volume of the material; a separator such as an iron…