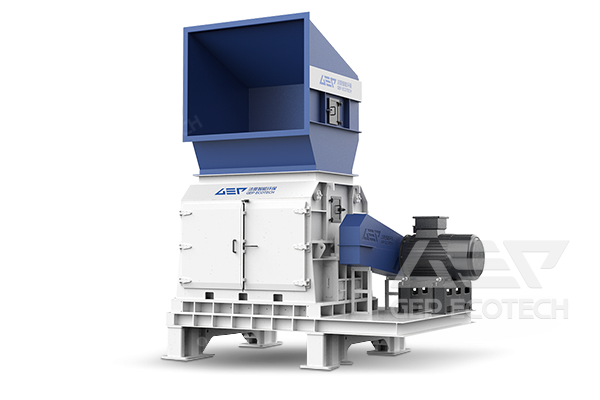

Fine shredder can crush materials into smaller, uniform pieces. The moving knife and fixed knife of the fine shredder make regular shearing actions, and cooperate with the control of the aperture of the screen to crush the materials into the expected size.

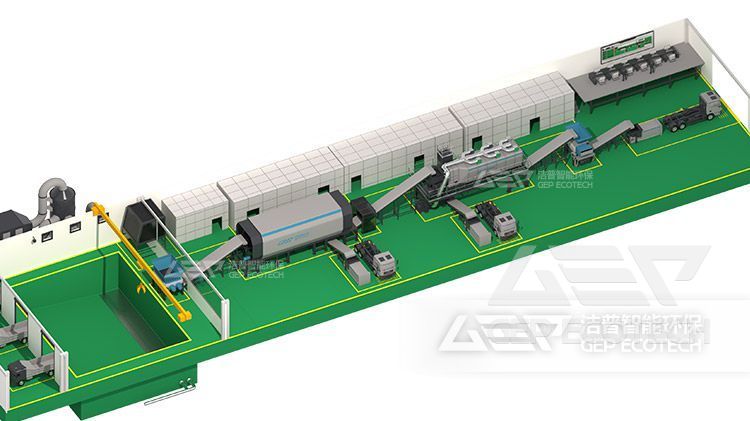

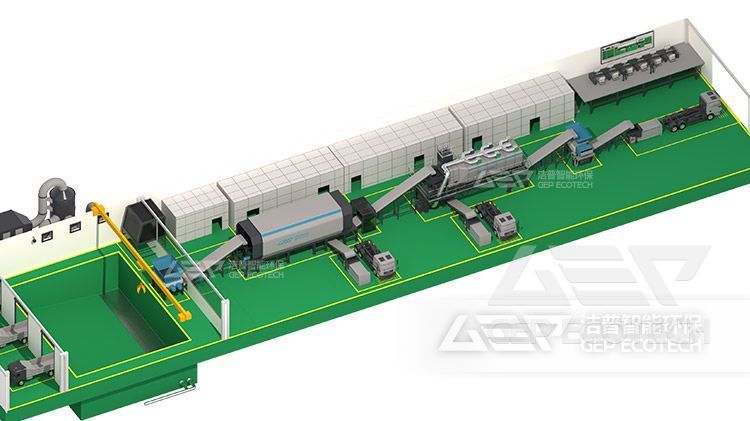

Unsure how to configure your 3-stage shredding line for MSW, industrial & commercial waste? Our engineering guide breaks down optimal setup for maximum uptime, efficiency, and ROI (Return on Investment).How Should a Triple-Stage Shredding System…

Earlier this year, GEP ECOTECH's technical team visited a biomass processing facility in Southeast Asia to follow up on a GXB series fine shredder installed just over one years ago. This particular machine was configured for reducing tree branches, wood…

Efficient shredding, precise discharge, and holding of complex materials!GXB biomass sherdder, specially designed for the resource utilization and disposal of various types of biomassEasily handle material handling capacities ranging from 3.5 to 16 tons/…

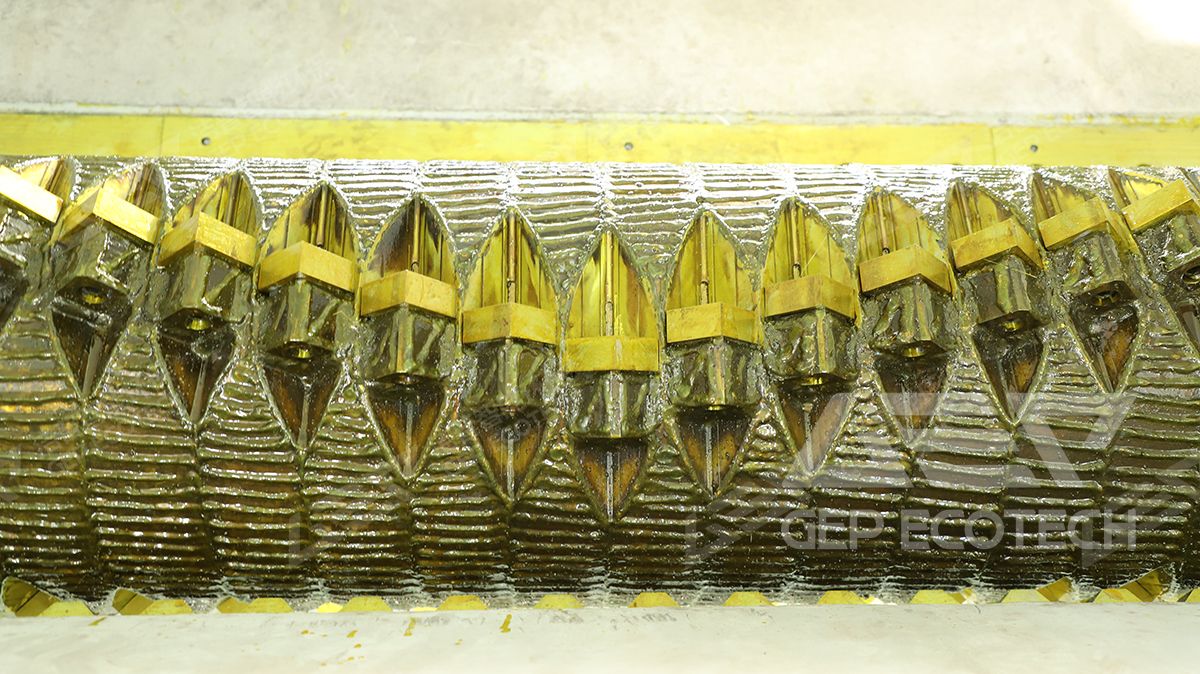

The GXB biomass fine shredder is specially designed for the fine shredding stage in biomass recycling lines. It features a large-diameter rotor to increase linear velocity and rotational inertia and a large, adjustable screen area ensures effective…

In order to cope with energy cost pressure and reduce carbon emissions, many cement companies are actively looking for alternatives to coal-fired power generation. Waste textiles, with their advantages of considerable calorific value (average calorific…

In recent years, twin-shaft shredders have garnered widespread recognition as primary shredders in solid waste crushing applications. However, single-shaft shredders hold a distinct advantage over their double-shaft counterparts in their ability to…

Polyurethane foam waste, known for its resilience and durability, has posed challenges in effective waste management. However, with the advent of advanced shredding technologies, it is now possible to efficiently shred polyurethane foam waste and obtain…

In the cement industry, alternative fuels refer to those that can replace traditional fossil fuels, including biomass alternative fuels and non biomass alternative fuels. These alternative fuels are usually prepared from combustible waste, such as waste…

Wind power generation, as a representative of clean energy, has been developing rapidly. The design life of wind turbines is approximately 20-25 years, and a large number of wind turbines are retired every year. The valuable parts of wind turbines for…

Fine shredders for rice straw shredding are specialized machines designed to break down rice straw into smaller, fine particles for various applications. Here are details regarding the types of fine shredders and the uses of shredded rice straw:Types of…

Relying on GEP ECOTECH's strong R&D and manufacturing capabilities and rich project operation experience, the GEP ECOTECH's shredder has won widespread recognition in the market.Double-shaft shredderDouble-shaft shredder is a universal solid waste…

The technology of cement kiln collaborative disposal of household garbage relies on the original decomposition furnace, rotary kiln and other high-temperature kilns of the new dry pre-decomposition clink production line to realize the reduction, resource…

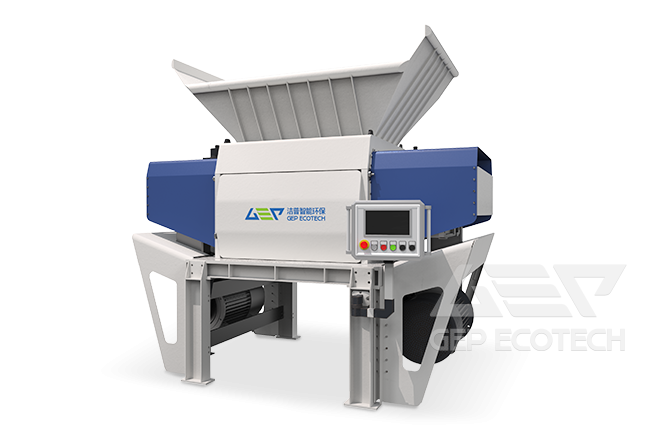

GSE-3 series European version single shaft fine shredder is the third generation enhanced product of GEP ECOTECH single shaft fine shredder series. It not only comprehensively adjusted the structure design, but also strengthened the equipment as a whole…

The European version fine shredder is a star product of GEP ECOTECH. With the increasing demand for fine finishing after more materials are recycled, the sales volume of it in the past two years has been close to that of the "Big Brother" -- double shaft…

GSD is a powerful high-standard fine shredder that can quickly shred materials to the required shape and size. GSD uses dual rotors to shred materials, which is more efficient and has a larger production capacity.

The GSS series single rotor shredder is suitable for processing a wide range of materials to a small and uniform size, with a maximum capacity of around 1 - 20 tons per hour and a discharge size of 30 to 120 mm, depending on the model of the machine, the…

Whether it is the secondary crushing of fuel derived from domestic waste, fine plastic crushing, domestic waste crushing and other fields, the disposal efficiency of the single-shaft shredder is leveraged! So single shaft shredder how much they cost?…