Renovation waste disposal market outlook is broad

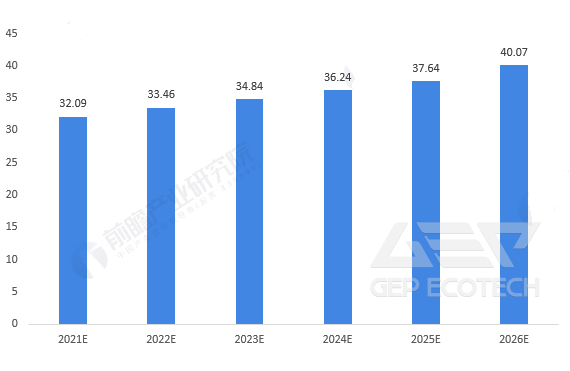

At present, the amount of construction waste in China accounts for about 40% of the total amount of municipal waste, the stock is 10 times that of domestic waste, and the growth rate is 6 times that of domestic waste, and it has become the first major source of municipal waste. In 2021, the amount of construction waste generated in China reached 3,209 million tons, and the amount of waste generated in 2026 is expected to exceed 4 billion tons.

Prediction of construction waste production

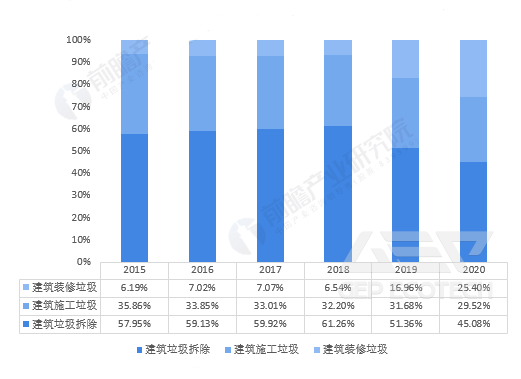

According to the source of construction waste, China's construction waste can be divided into three categories: construction waste generated during the demolition of old buildings (hereinafter referred to as "demolition waste"), construction waste generated during the renovation of existing buildings (hereinafter referred to as "renovation waste"), and construction waste generated during the construction of new buildings (hereinafter referred to as "construction waste").

Statistics show that in 2020, China's demolition waste accounted for about 45.08%, construction waste accounted for about 29.52%, and decoration waste accounted for about 25.40%. According to this calculation, China's annual generation of renovation waste is about 800 million tons, if calculated at 35 yuan / ton (transportation and disposal fees), the renovation waste treatment market size will be more than 28 billion yuan, with a broad space.

Distribution of sources of construction waste

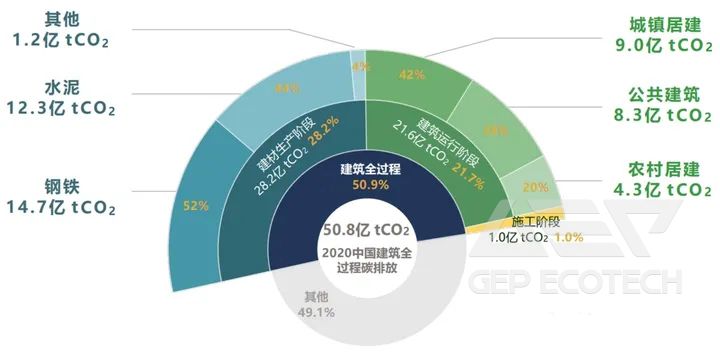

The construction industry has a long way to go to reduce carbon emissions

According to the 2022 China Building Energy Consumption and Carbon Emission Research Report released by China Building Energy Conservation Association, China's total carbon emissions will be 9.9 billion tons in 2020, of which the total carbon emissions from the whole process of construction (including the production stage of building materials, the construction stage of the building, and the operation stage of the building) will be 5.08 billion tons, accounting for 50.9% of the national carbon emissions. As a major carbon emitter, the construction industry has a long way to go to reduce carbon emissions.

The total and proportion of carbon emissions from the entire construction process in China in 2020

Comprehensively interpreting the national and local policies, the implementation path of carbon reduction and emission reduction in China's construction industry mainly includes six major categories: source reduction, energy transformation, energy efficiency improvement, model upgrading, resource recycling, and carbon-negative technologies. Among them, resource recycling refers to creating a recycling system for renewable resources in construction through the categorization, treatment and recycling of construction solid waste, effectively reducing carbon emissions in the initial production and disposal process.

To sum up, the construction waste treatment enterprise, which "owns" 800 million tons of renovation waste resources, will play a pivotal role in the construction industry on the road of carbon reduction and emission reduction.

Construction Waste Disposal Business Dilemma

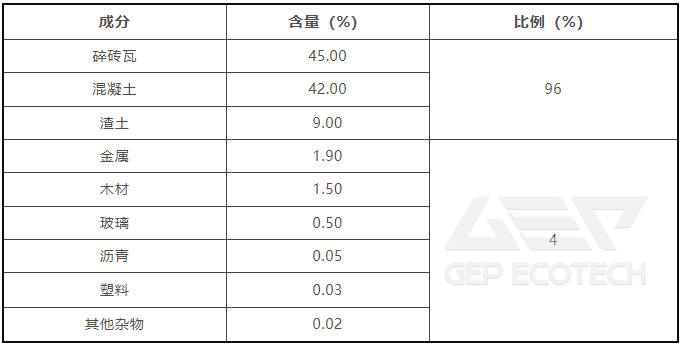

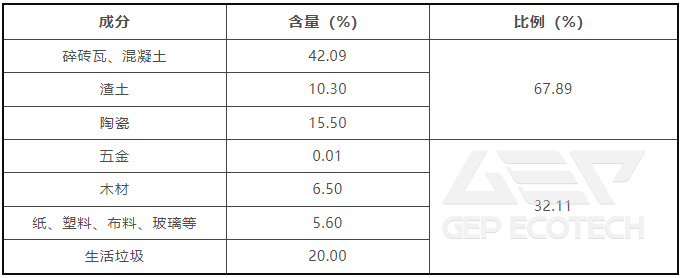

According to the garbage composition research report, demolition waste and construction waste is mainly composed of broken masonry, concrete and slag, accounting for 96%, other materials accounted for only 4%; while the proportion of the composition of decoration waste, these materials accounted for only 52%, plus ceramics of a similar nature, also less than 70%. Since there is about 30% of the composition of the difference, then in the demolition, construction waste disposal process with the comfortable technical solutions and production line equipment cannot be directly set for renovation waste disposal. This requires that construction waste disposal enterprises must cooperate with suppliers who have experience in renovation waste disposal, mature solutions and independent equipment, which is what we often say - to give professional things to professional people to do, not only to improve quality and efficiency, but also to reduce risks and costs.

Composition and proportion of demolition waste and construction waste

Composition and proportion of decoration waste

Usually, heavy materials such as broken bricks and tiles and concrete in renovation waste will be made into recycled aggregates through crushing, sorting and other processes, and reapplied to the construction and building materials industry to realize resource utilization. And wood chips, paper, fabric, plastic and other light materials, due to the components are too complex, sorting too laborious, processing is too difficult, and by the construction waste disposal enterprises piled up idle, occupying a large area of plant space; or by these enterprises to the waste incineration power plant to pay high fees for the treatment, so both aggravate the burden of the enterprise's operations, but also caused this part of the waste of resources.

So is there a solution to kill two birds with one stone?

Solution: Lightweight alternative fuel preparation system for renovation waste

GEP's lightweight alternative fuel system for renovation waste can easily solve the problem of "difficult" lightweight materials in renovation waste, and can also convert these lightweight materials into alternative fuels, which is currently a "hot" carbon emission reduction tool, which also means that construction waste treatment enterprises will change from "payers" to "fee payers", which will increase the new profit growth point for their own enterprises, and at the same time, also contribute to the entire construction industry or even the cement industry (potential buyers) in terms of carbon emission reduction.

Preparation system of light substance alternative fuel for decoration waste

After the disposal process of crushing, magnetic separation, fine crushing and other disposal processes of the light materials in the renovation waste, the combustible bulk materials obtained can be sold directly, or RDF molding equipment can be added at the back-end to further process the bulk materials into RDF fuel rods, which will have a higher calorific value. (The process design and equipment configuration of this system is customized, and equipment such as wind sifter, trommel screen, baler, etc. can be added according to customer needs.)

Primary crushing

Magnetic separation for iron removal

Secondary fine crushing

Terminal forming

The calorific value of combustion of these RDF fuels is about 5000kcal/kg, which is equivalent to more than 80% of standard coal, while the carbon dioxide emission is only 1/4 of that of coal, and the selling price can be up to more than 350 RMB/ton.

With such a renovation waste disposal experience of more than ten years, dozens of renovation waste project cases, more than one hundred product patents of the supplier cooperation, share the ten billion yuan renovation waste disposal market, construction waste disposal enterprises, you are willing to?