Vibrating screen is one of the main types of industrial screening equipment. There are many mechanical screening solutions for solid waste disposal, recycling and aggregate production lines. However, vibrating screen provides many unique advantages, making it a wide choice for various industrial applications.

What is a vibrating screen?

As the name implies, the design of vibrating screen is based on the principle of transferring vibration to the screening surface, so as to separate and classify different particles according to size.

No matter how the machine is designed, the principle is the same: vibration will destroy the surface tension between particles, thus forcing them to separate. The particles with too small size are called "fine particles" and fall down through the screening surface. At the same time, oversized particles are carried on the screen surface. This is an important application in many industries, especially mineral processing.

Unique advantages of vibrating screen

Due to its unique design features, vibrating screen is more widely used in solid waste treatment and aggregate production lines than other screening equipment. We will further describe these advantages in detail below.

Improve processing and material quality

Although some screening equipment is more suitable for different materials, vibrating screen has many advantages in aggregate and mining material processing. Vibrating screen equipment is particularly sophisticated, which can meet the fineness requirements of these industries. Their design creates the force required to separate oversized particles from fines, making it easier to recycle products even when dealing with materials that require significantly smaller separation sizes. This leads to higher yields and improved overall quality of screened products.

Reduce operating costs

Vibrating screens are known for their rugged design. Due to the simple working principle and streamlined design of modern machines, the price of vibrating screen is generally cheaper than other types of screening machines. This will reduce the initial investment of the project to a certain extent.

In addition, compared with more complex machinery, vibrating screen can operate with lower energy consumption, thus saving the continuous operating cost for enterprises. Also, as the higher frequency vibration is directly transmitted to the screening surface, it is only necessary to replace the screening medium regularly. This helps to save maintenance and repair costs that are typically associated with the selection of other screening equipment.

Less maintenance and downtime

Maintenance and downtime caused by repairs or equipment failures can result in significant loss of productivity and profits. Many types of screens will experience severe wear, especially in demanding applications such as aggregate processing. However, the vibrating screen has the advantage of less maintenance and downtime. This is the result of their design, whose center is to transfer the vibration force only to the screening surface.

In addition, the design and manufacture of high-quality vibrating screening equipment make other parts of the machine less affected by vibration force. In more complex designs, the machine is constructed to allow adequate absorption and damping of vibrations outside the screen medium. This has less overall wear on the machine, further reducing downtime and maintenance.

Higher screening efficiency

Although there are various screening equipment on the market, vibrating screen is an ideal choice when operation requires a simple solution that can handle higher feed flow. In fact, the vibrating screen has a high working efficiency at a continuous high flow rate. For other types of screening equipment, the same material throughput may result in clogging of the sieve or slower material feeding.

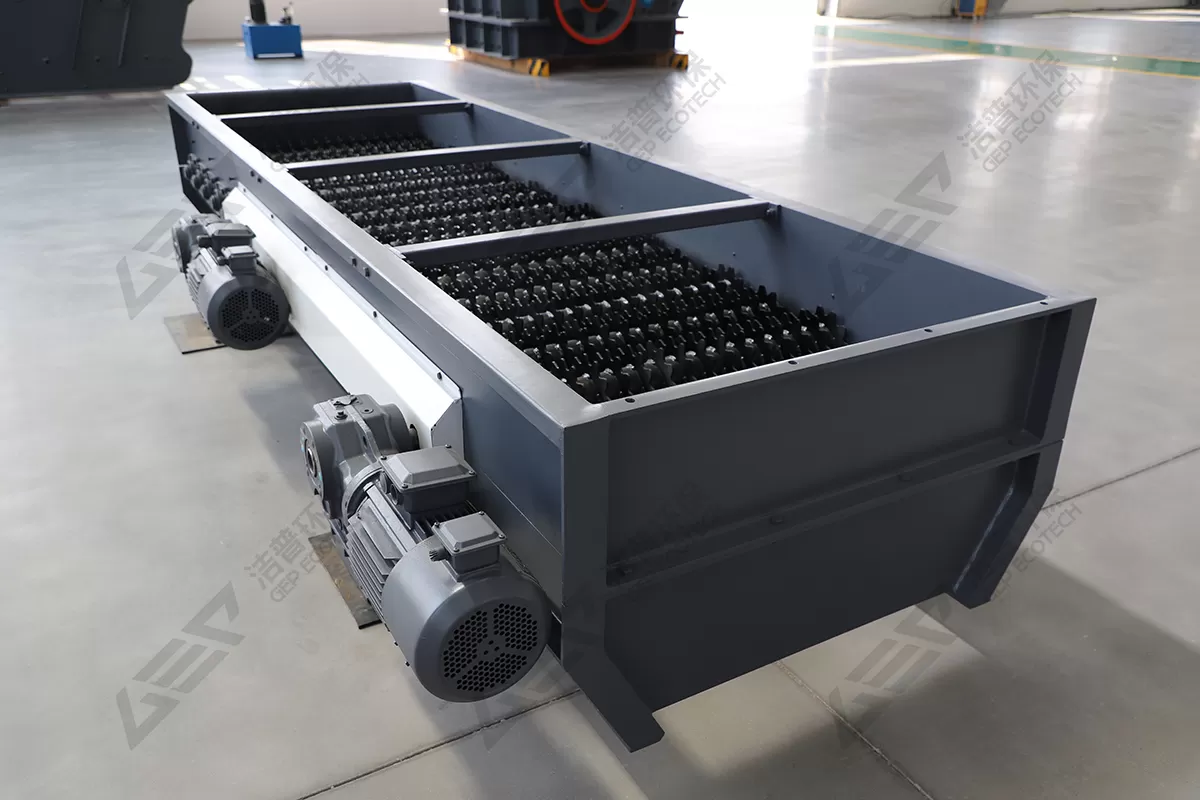

GEP ECOTECH has developed many types of vibrating screens after considering harsh applications and challenging materials. GEP design adopts a unique double vibration inverted flow screening process, which helps to ensure smooth operation by eliminating screen hole blockage, thereby reducing maintenance, downtime and drive efficiency. Learn more about the vibrating screen Contact us!