Carpets are usually made of a number of different materials, including fibers, glue, sponge, and more. These different materials complicate the shredding and handling of carpets. Carpet fibers may be natural, such as wool, or synthetic, such as polyester. Additionally, rugs often have chemicals added during the manufacturing process, such as glue, to keep the fibers firmly bonded. Therefore, choosing the right shredder is crucial to effectively process these materials.

The role of carpet shredder

The carpet shredder is an important machine for recycling waste carpets. Its function is to tear the waste carpet into small pieces for the recycling process. At the same time, the shredded waste carpet can greatly reduces the transportation cost. For recycling carpet, shredding is the first step.

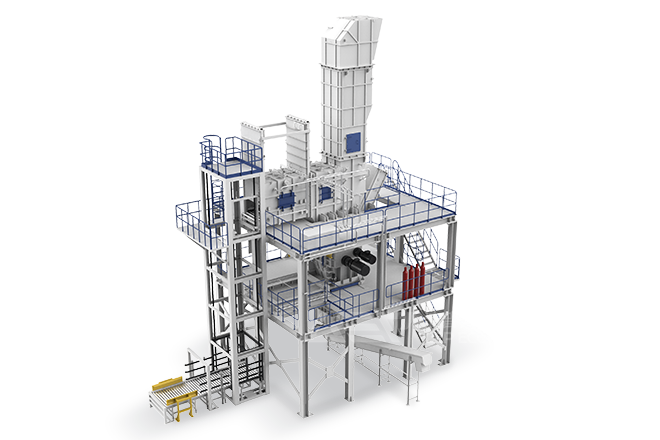

Carpet shredder for sale

Different manufacturers supply different types of shredders. Taking GEP ECOTECH as an example, there are mainly single-shaft shredders and double-shaft shredders. For shredding carpets, single-shaft shredders have a finer output, while twin-shaft shredders have a higher output. Taking into account that the fabric is easy to cause jamming when shredding, the GEP shredders are designed with anti-winding and automatic flip functions, which can smoothly complete the shredding task of carpets. Which model to choose depends on the expected productivity and the output size of the waste carpet after shredding, etc. For large-scale shredding, a double-shaft shredder is an ideal choice, and a single-shaft shredder is an ideal choice for finer discharge requirements. Of course, there are also many projects that choose multiple shredders to work together.

Recycling carpets is a challenging yet highly rewarding task that reduces resource waste and reduces adverse environmental impacts. Choosing the right shredder is critical to effectively processing carpet material. GEP shredders are ideal for recycling carpets due to their multiple cuts, adaptability and stability. If you want to know more, come to contact us!