Bulky waste recycling is a good thing for no matter environment pollution, our living environment, but also a good business activity. So bulky waste recycling system is more and more popular. GEP have rich experience on bulky waste recycling, we have exported many bulky waste recycling production line to other countries, today I will introduce you a common price of a bulky waste recycling system.

Usually the bulky waste shredder line is made by chain belt conveyor, double shaft shredder, output belt conveyor, iron separator, and so on.

The bulky waste are sent to the conveyor beltto enter to the double shaft shredder, the shredder use two relatively rotating cutting shafts to shear each other, and the tearing principle breaks the material. Large pieces of garbage are quickly cut and shredded into small pieces, and the material is then transported to a magnetic separatorafter shredding.

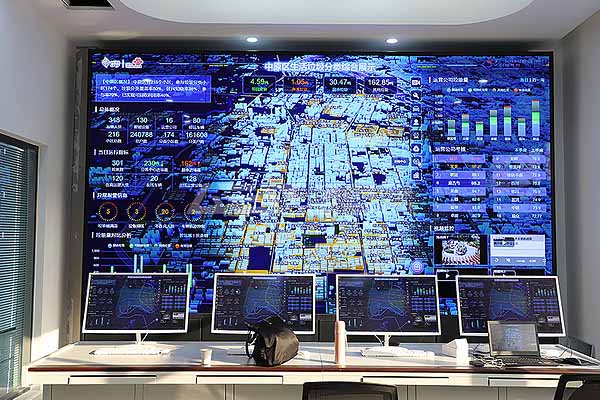

Under magnetic force, metal objects such as nails, wire, iron sheetwill be automatically sorted out for centralized recycling and reuse. The rest of the materialare sent to the transport truck, waiting for the next processing process. In the wholeproduction process,the operator can monitor the shreddingand sorting process in real time through GEP GI intelligent monitoring system, which can effectively reduce the equipment operation failure rate and maintenance time, reduce the maintenance and operation cost, and greatly improve the operation efficiency of the production line.

The production line adopts the closed design in the shreddingand blanking area and is equipped with intelligent pulse dust removal systemwhich control the dust to improve the workshop environment.

The whole system is well designed, with compact structure, small area, high efficiency, low noise and low dust, is a very good bulky waste shredder solution.