In the realm of sustainable waste management, the utilization of food waste for biogas production has emerged as a potent solution. An integral component in this process is the application of shredders, which play a pivotal role in enhancing the efficiency and overall success of the anaerobic digestion journey from food scraps to biogas. This article delves into the rationale behind employing shredders in the context of kitchen waste and explores which type of shredder is best suited for optimizing biogas production.

Why Shredders for Food Waste Biogas Production?

- Enhanced Digestion Efficiency: Shredders break down food waste into smaller, more digestible fragments. This increased surface area exposes more organic matter to microbial activity during anaerobic digestion, leading to higher gas production.

- Accelerated Biogas Yields: Smaller particles undergo digestion at a faster rate. Shredding food waste facilitates a swift and efficient digestion process, resulting in accelerated biogas yields and maximizing the overall output.

- Uniform Feedstock Composition: Shredders ensure a consistent and uniform feedstock for the anaerobic digester. This uniformity is crucial for maintaining optimal conditions within the digester, preventing potential clogs, and promoting efficient gas production.

- Prevention of Compaction Issues: Unshredded food waste tends to compact, hindering the flow of material within the digester. Shredding mitigates this compaction, allowing for smoother material movement and preventing operational disruptions.

Choosing the Right Shredder for Biogas Production from Food Waste

Efficiently managing food waste is essential for sustainable waste management practices and renewable energy production. In the context of biogas production from food waste, selecting the appropriate shredder is crucial to ensure optimal processing and maximize biogas yield. Among the various options available, the GDF dual-shaft shredder from GEP ECOTECH emerges as an excellent choice for effectively shredding food waste and facilitating biogas production. Here's why the GDF dual-shaft shredder is highly suitable for this application:

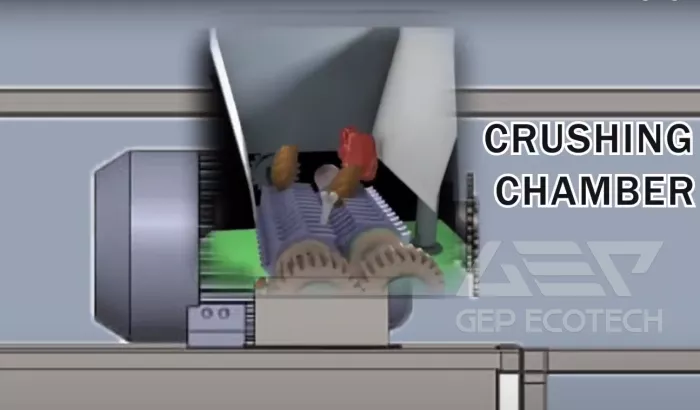

- Efficient Shredding Performance: The GDF dual-shaft shredder is specifically designed to efficiently shred food waste into small, uniform particles. Equipped with two counter-rotating shafts and sharp blades, it ensures thorough and effective waste reduction, promoting efficient digestion and biogas production.

- Versatility in Processing: This shredder can handle a wide range of food waste materials, including fruits, vegetables, meat scraps, bones, seafood shells, and more. Its robust construction and powerful shredding mechanism enable it to process various types of organic waste with ease, contributing to a diverse feedstock for biogas production.

- Reduced Risk of Clogging: The dual-shaft design of the GDF shredder minimizes the risk of jamming or clogging, even when processing fibrous or stringy food waste materials. The counter-rotating shafts work together to continuously feed and shred the waste, preventing blockages and ensuring smooth operation of the biogas production process.

- Durable and Reliable: Built to withstand the demands of continuous operation, the GDF dual-shaft shredder is constructed from high-quality materials and equipped with heavy-duty components. It is durable, reliable, and long-lasting, ensuring consistent performance in biogas production facilities.

- Low Maintenance Requirements: The GDF shredder has lower maintenance requirements compared to other shredder models. Its robust construction and efficient shredding mechanism minimize wear and tear, reducing the need for frequent maintenance and downtime, thus maximizing operational efficiency and biogas production uptime.

In the quest for sustainable energy solutions, the integration of shredders into food waste biogas production processes proves indispensable. The careful selection of the appropriate shredder type ensures not only efficient material preparation but also contributes significantly to the success of converting food waste into a valuable source of biogas. GEP has provided shredder equipment for multiple food waste biogas projects. Welcome to contact us for more equipment details!