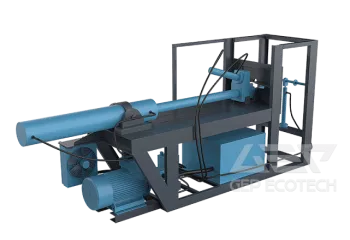

A shredder for rubber shredding is a specialized industrial machine designed to effectively process rubber materials into smaller, more manageable pieces. These machines are crucial in various industries where rubber recycling or processing is required, such as tire recycling, rubber manufacturing, and rubber product production.

Types of shredder for rubber shredding

There are several types of shredders used for rubber shredding, each designed for specific applications and requirements. Here are some common types of shredders used in rubber processing:

- Single-Shaft Shredder: Single-shaft shredders have a rotating shaft equipped with blades or knives. They are suitable for fine shredding a wide range of rubber materials, including tires, rubber sheets, and smaller rubber components. Single-shaft shredders are versatile and offer efficient size reduction.

- Double-Shaft Shredder: Double-shaft shredders have two interlocking, counter-rotating shafts with blades or knives. They are known for their high throughput capacity and ability to shred large rubber items, such as whole tires. Double-shaft shredders provide effective and consistent shredding results.

- Four-Shaft Shredder: A four-shaft shredder is a powerful and versatile machine used for rubber shredding and processing. As the name suggests, it features four interlocking, counter-rotating shafts equipped with cutting blades or knives. This design offers several advantages for efficiently shredding rubber materials, no matter how difficult the crushing task is, it can easily handle it.

- Granulators: Granulators are specialized machines that combine shredding and granulating processes. They can reduce rubber materials into small granules or particles with a specific size range. Granulators are often used in recycling applications where precise size control is required.

Selecting a Rubber Shredder

When choosing a rubber shredder, consider the following factors:

- Type of Rubber: Rubber shredders can handle various types of rubber, including tires, rubber sheets, conveyor belts, and more. Ensure the machine is suitable for the specific type of rubber you need to shred.

- Shredded Output Size: Determine the desired shredded rubber output size for your application, as different machines can produce varying particle sizes.

- Capacity: Consider the throughput capacity of the shredder, which is typically measured in pounds or kilograms per hour. Select a machine that matches your production requirements.

- Maintenance and Service: Evaluate the ease of maintenance and the availability of replacement parts and service support from the manufacturer.

- Safety Features: Prioritize machines with robust safety features to protect operators and prevent accidents.

- Cost and Budget: Rubber shredders come in various sizes and capacities, so consider your budget and cost-effectiveness when choosing a machine.

- Environmental Impact: Some rubber shredders are designed with energy-efficient features and environmentally friendly materials. Consider machines that align with your sustainability goals.

A rubber shredder is an essential machine for processing rubber materials in various industries. Choosing the right shredder with the appropriate features and capacity is crucial for efficient and effective rubber shredding, recycling, or processing. GEP ECOTECH can provide a variety of high-quality rubber shredders, please contact us to learn more!