Let's be real – crushing empty paint drums can be risky business. Even “empty” containers often have leftover chemicals, flammable vapors, or sticky residues that can cause fires, explosions, or toxic exposures. Many facilities still use basic shredders with open conveyors and standard fire extinguishers, but that’s not enough for true safety.

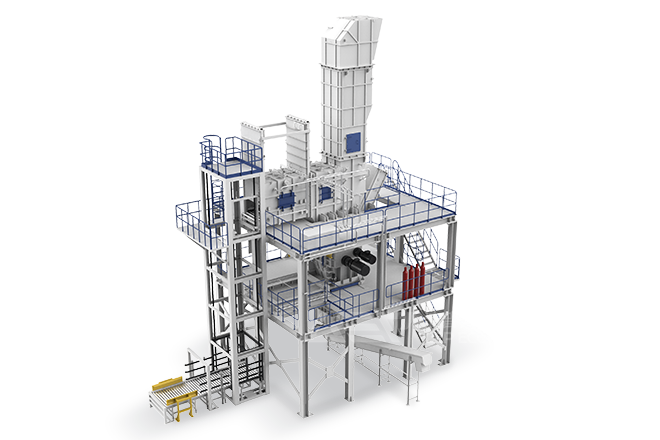

That's why we designed a closed-loop, nitrogen-protected paint drum crusher specifically for U.S. hazardous waste processors. Here's how it works – and why it's a game-changer for safety and efficiency.

No Oxygen, No Fire – It's That Simple

Our system doesn't just react to fires—it prevents them.

- Sealed from start to finish: Drums are fed into a nitrogen-filled chamber before crushing, eliminating oxygen (and the risk of ignition).

- No sparks, no surprises: Even if a hidden solvent ignites, the nitrogen-rich environment smothers flames instantly.

- Zero fumes escaping: Unlike open shredders, our fully enclosed system keeps workers safe from harmful vapors.

Built for the Worst-Case Scenario

We assume things could go wrong – so we've added layers of protection:

- Instant CO₂ fire suppression – Detects and extinguishes flames in milliseconds.

- Explosion vents – Safely redirects pressure away from operators if an unexpected blast happens.

- No manual unjamming – Hydraulic access panels let you clear blockages without opening the crushing chamber.

Customized for Your Facility

We know every recycling operation is different. That's why our systems are modular – whether you process 100 drums a day or 10,000, we can tailor the size, automation, and safety features to fit your needs.

Ready to crush paint drums the safer, smarter way? Let's talk about a system that keeps your team protected and your production running smoothly. Contact us today for a free consultation.