When it comes to biomass processing, two critical pieces of equipment are the double shaft shredder and the wood chipper. Both serve unique purposes and offer distinct advantages, making them essential for different aspects of wood and biomass waste management. This article explores the differences between these two machines, covering their features, suitable materials, and production capacities.

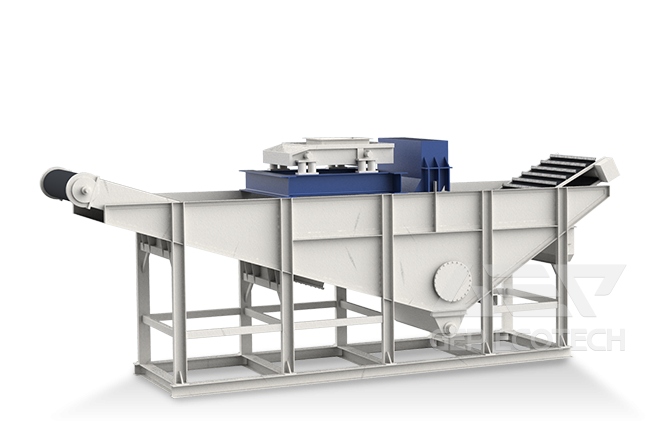

Double Shaft Shredder

Features:

- Design: The double shaft shredder consists of two parallel rotating shafts with interlocking blades that shear material into smaller pieces.

- Construction: Built with robust and durable materials to withstand heavy-duty operations. Typically equipped with high-torque, low-speed motors to handle tough and bulky waste.

- Operation: Can operate continuously for long periods, making it suitable for industrial applications.

Suitable Materials:

- Biomass Waste: Includes agricultural residues, forest waste, and other organic materials.

- Wood Waste: Handles large branches, stumps, and other tough wood materials.

- Other Materials: Can also shred plastic, rubber, and metal, making it versatile for various waste management needs.

Production Capacity:

- Output Size: Produces coarser output compared to a wood chipper, which is useful for preliminary shredding before further processing.

- Throughput: High throughput capacity, capable of processing several tons of material per hour.

Wood Chipper

Features:

- Design: Wood chippers feature a rotating drum or disc with sharp blades that slice wood into chips.

- Construction: Typically lighter and more compact compared to double shaft shredders, designed for mobility and ease of use.

- Operation: Operates at higher speeds to produce fine wood chips quickly.

Suitable Materials:

- Wood Waste: Primarily designed for smaller branches, leaves, and garden waste.

- Biomass: Suitable for producing wood chips used as mulch, compost, or biofuel.

Production Capacity:

- Output Size: Produces uniform and fine wood chips, ideal for direct use in biofuel production, landscaping, and agricultural applications.

- Throughput: Generally lower throughput compared to double shaft shredders, suitable for smaller scale operations or specific chipping tasks.

Both the double shaft shredder and the wood chipper play crucial roles in biomass processing, each offering unique benefits tailored to different needs. The double shaft shredder is indispensable for heavy-duty and large-scale waste management, capable of handling a wide range of materials. In contrast, the wood chipper excels in producing fine wood chips for immediate use in biofuel production, landscaping, and agricultural applications.

Understanding the differences between these two machines helps businesses and industries choose the right equipment for their specific biomass processing needs, optimizing efficiency, and contributing to sustainable waste management practices. If you need more professional equipment selection guidance, contact GEP ECOTECH!