The technology of cement kiln collaborative disposal of domestic waste relies on the original calciner, Rotary kiln and other high temperature kilns of the new dry precalcining clinker production line to reduce, resource and innocuous domestic waste. Due to its high disposal efficiency, low investment, short construction cycle, thorough harmless disposal, and good environmental indicators, it has been increasingly widely used.

The collaborative disposal of domestic waste in cement kilns can be divided into two processes: pre-treatment of domestic waste and incineration in kilns. The pre-treatment process involves shredding and screening the original ecological domestic waste, ultimately forming two parts: combustible and non combustible. Combustibles generally include waste plastics, paper, rubber clothing, tree branches and leaves, etc. Because of their calorific value, they can be used as Alternative fuel to enter the calciner of the cement production line for incineration, and play a thermal effect to reduce the use of raw coal in the cement production process; Non combustible materials generally include bricks, tiles, stones, sand, fruit peels, bones, glass, metals (separately selected and sold as waste), etc. The components of non combustible materials are similar to those of cement production raw materials, and can be used as clay substitutes in cement production lines to save raw materials.

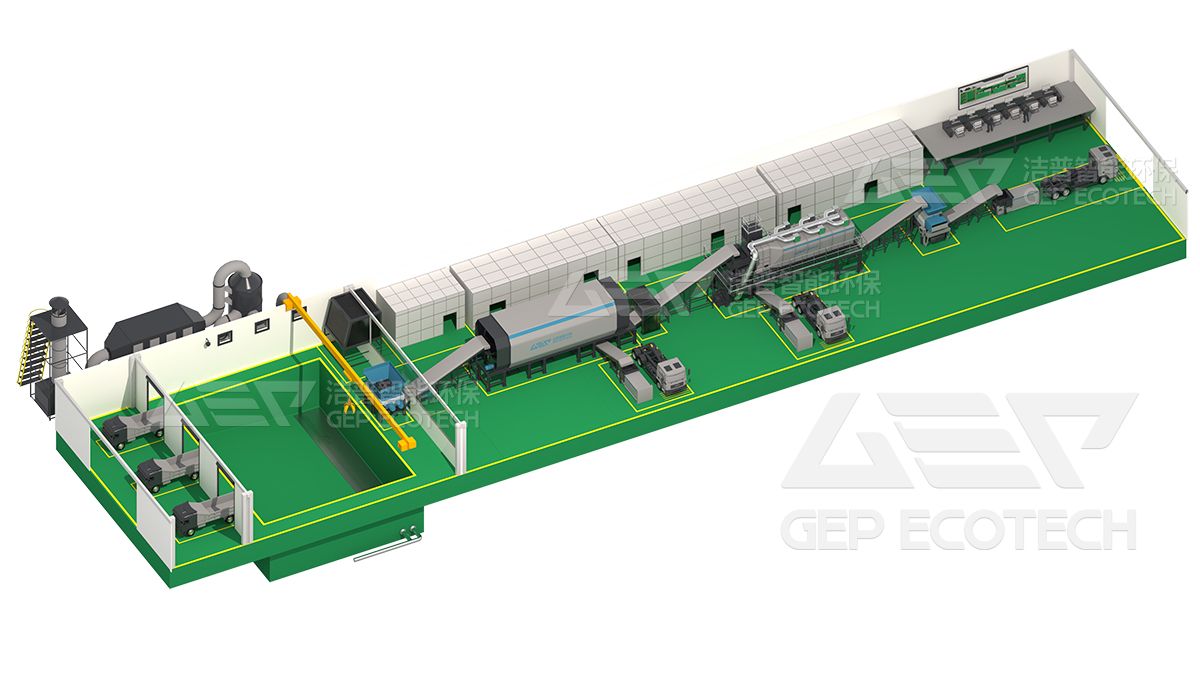

The pre-treatment of domestic waste generally uses a disposal system composed of pre-shredder, fine shredder, rotary drum screen, magnetic separator, wind sifter, conveyor, dust collectors, and GI intelligent monitoring system. The system has good shredding effects, fine sorting, high automation, and low energy consumption. (Based on the different material compositions and processing requirements of different projects, we can flexibly design treatment plans to improve overall disposal efficiency and effectively reduce project operating costs.)

According to incomplete statistics, a 500 ton/day cement kiln collaborative disposal of domestic waste production line can digest 155000 tons of domestic waste annually, save 20000 tons of standard coal for the cement production line throughout the year, and save about 40 acres of land annually for reducing landfill land for domestic waste in surrounding areas. The economic, social, and environmental benefits are significant.