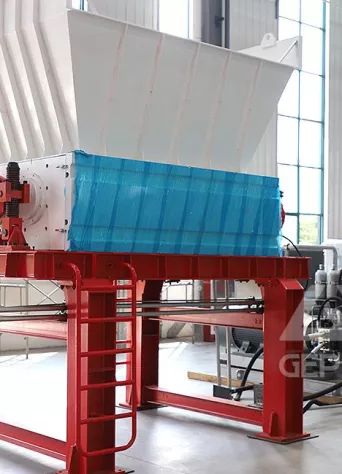

Large-scale waste treatment applications face many challenges. For example, the large-scale processing requirements put huge pressure on subsequent treatment equipment, and the wide range of changes in electrical load caused by different types and sizes of waste, etc., which will cause huge uncertainties to the entire system. The addition of a pre-shredder to the disposal system helps to reduce and disassemble the material before it is sent to the main shredder, reducing risks and at the same time homogenizing the feed. Pre-shredders are widely used in projects such as car shell shredding and large-scale obsolete waste disposal.

The pre-shredder is installed in front of the main shredder to help reduce and break up the material before it is fed into the main shredder. This helps to extend the life of the main shredder cutters and prevents non-shreddable and flammable materials from entering, while reducing peak power loads and keeping the line running smoothly. The pre-shredder also homogenises the feed and helps to control the feed rate to the main shredder, thereby increasing throughput and reducing unit processing costs.

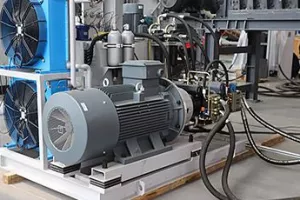

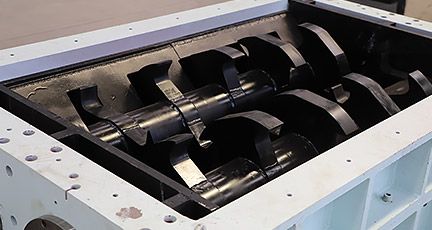

The GC pre-shredder uses a low speed, high torque double hydraulic motor to drive the cutter rolls directly. It uses the interaction between the cutters and the middle comb plate to shear, tear and pull the material, and is mostly used as the first step in the shredding process of various solid wastes.