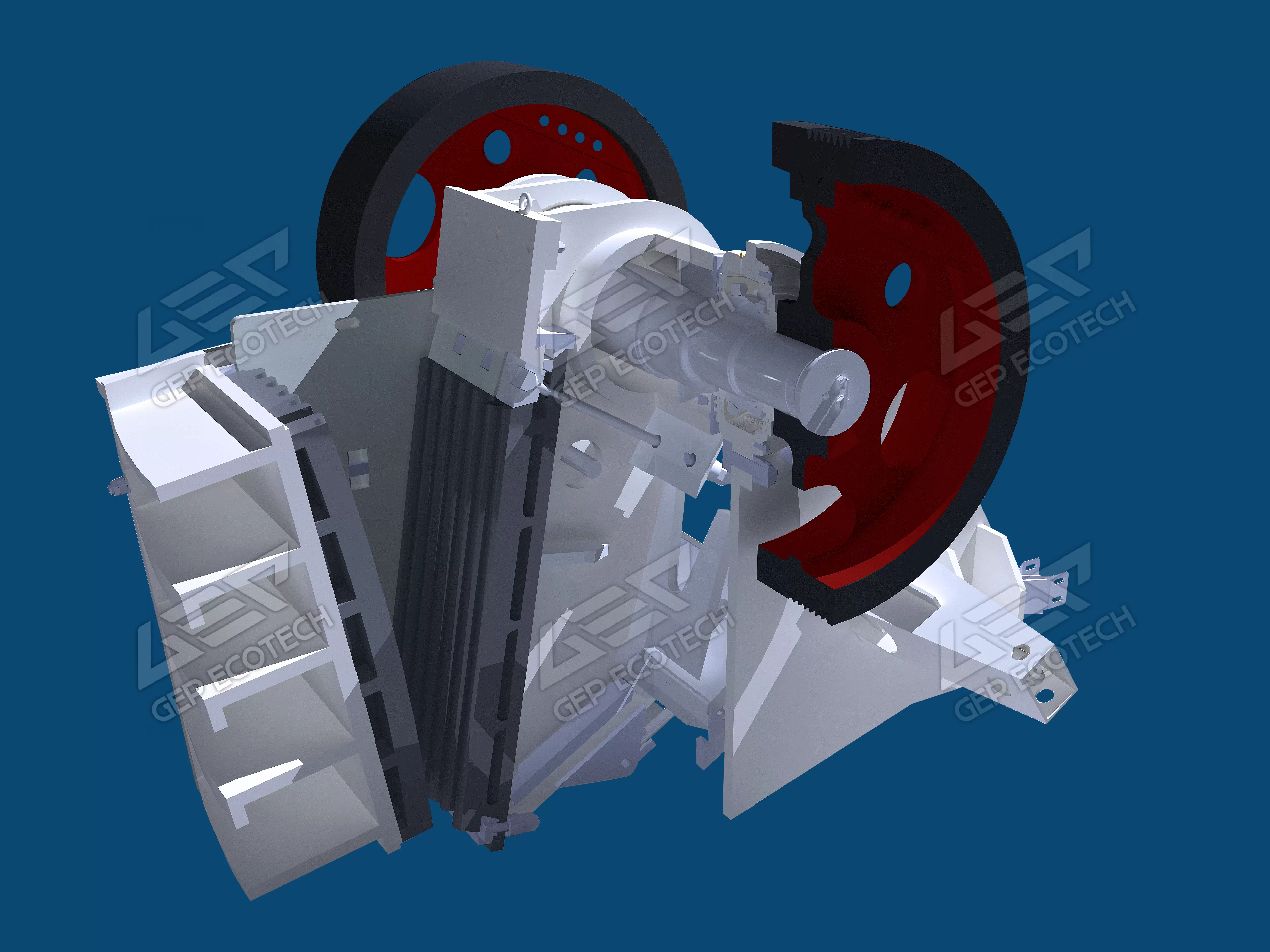

The jaw crusher is a versatile equipment that is actively used for crushing hard materials of rocks (stone, ore, concrete) to produces finished raw materials. Materials obtained by the crushing method are in high demand in various spheres of life. Jaw crushers are crushers in which material is crushed by pressure between the iron plates. In this case, one of the surfaces is stationary, and the second carries out swinging reciprocating movements.

The jaw crusher GEC series of GEP Ecotech is mainly intended for crushing structural elements (blocks of bricks, reinforced concrete slabs, etc.) of buildings and structures remaining after their dismantling. The jaw crusher can also be used for crushing other materials (stone, slag, etc.) both in a single version and as part of technological lines.

Advantages of Jaw Crusher

- Simple movement, provides the maximum resource of the crushing plates;

- Special steel for the crushing plates ensures maximum wear resistance of the crushing plates, which reduces the cost of operation and maintenance of the machine;

- Corrugated cheeks contribute to a more efficient crushing process and reduce operating loads;

- Outdoor design of the crusher ensures the efficiency and stability in all weather conditions;

- the design of the crusher provides the possibility of transportation by any means of transport and easy installation on site.

Jaw Crusher for C&D Waste

In construction and demolition waste treatment facilities, jaw crushers are the most widely used type of crushing equipment. This is because C&D waste includes high-hardness concrete, asphalt and other items, jaw crushers are used as primary treatment not only has high efficiency, but also has low loss, which can help the overall project to reduce operating costs.